How We Work is an interview and essay series by Contrary dedicated to surfacing insights about important parts of the economy that have gone unnoticed or under-explored by the startup ecosystem. It profiles the people who power the modern world and the tools, systems, and processes they interact with every day.

***

Beneath the bustling streets and skyscrapers of modern urban landscapes lies a hidden world of complex engineering. Tunnels crisscross beneath today’s cities and beyond, facilitating the flow of water, gas, and sewage; data and telecommunications; public transport and freight. The job of building these underground pathways and ensuring they remain strong and stable long into the future belongs to tunnel engineers.

The concept of tunneling is almost as old as civilization itself, tracing back to the mines, aqueducts, and underground passageways of the ancient world from Mesopotamia and China to Egypt and Rome. Early tunnel builders, lacking the advantages of modern machinery and computational modeling, relied on simple tools, ingenious planning, and sheer force of manpower to build their causeways beneath the earth.

The Industrial Revolution changed the role of the tunnel engineer dramatically with the advent of railroads, subways, and – later – automobiles. No longer were tunnels merely used to conduct the flow of water, extract resources, or bury the dead; now they had to accommodate the transport of large, heavy machinery, often at high speeds. This necessitated a new breed of engineer, one with both an understanding of urban and civil engineering and a sophisticated knowledge of geology and soil science.

As urban areas continue to grow, both horizontally and vertically, the demand for efficient transportation and utility systems grows too. New challenges have emerged as subterranean construction becomes ever more complex and our urban landscape grows denser and more populous, requiring tunnels to be more resilient than ever before. Moreover, in the digital age tunnels also serve as conduits for data, helping move information in much the same way as they do cars, subways, and utilities.

The tunneling industry has recently seen major attempts at disruption, with Elon Musk’s Boring Company seeking to establish a reliable method to create low-cost, efficient tunnels that can accommodate various transportation systems such as cars or transit. As we’ve written about in a previous Foundations & Frontiers essay on the Frontier of Boring, it is still the case that most tunnel construction occurs as part of enormous, complex public works projects.

To understand how tunnel engineers do their work in more detail, we spoke with Theodora Vovou. Theodora is a senior tunnel engineer at Hatch, a New York-based consultancy. Theodora, who trained in Greece and the US, has worked in the industry both designing tunnels and managing major infrastructure projects for many years and brings a wealth of experience to bear in illuminating the way that tunnel engineering works today.

Three key insights

Source: Wikimedia Commons

1. Tunnel design is a complex discipline that requires a deep understanding of engineering and geology.

Tunnel engineering is a complex field, primarily due to the varying and often unpredictable geological conditions encountered during projects. Unlike structures such as bridges or buildings, tunnels more deeply penetrate Earth’s surface, meaning engineers have to account for a multitude of geological variables including soil types, rock formations, water tables, and seismic activity.

For example, certain soil types are prone to quick settlement, which could lead to tunnel collapse if not properly managed. Similarly, areas with high water tables require specialized waterproofing techniques to prevent tunnels from flooding. Additionally, in seismically active regions, the tunnel must be designed to withstand the forces generated by earthquakes, adding another layer of complexity.

This also makes tunnel engineering a difficult discipline to either teach or learn. Given it touches on both civil engineering and geology, there are only some schools and courses that focus on it. To make matters worse, open jobs in tunnel engineering are scarce and often require many years of experience, further limiting the number of people who can work in tunnel engineering. According to Theodora, many candidates with the requisite skills to become tunnel engineers often move to other engineering roles in different industries or stay in academia because of the job market.

As a result, tunnel engineers are relatively scarce and often geographically dispersed, which can create challenges in team coordination. Theodora describes working at a consultancy where the tunnel engineers were located all over the US because it was implausible to have them all in one office.

2. Software solutions used in tunnel construction are niche and often expensive.

Theodora described a wide suite of software products used by tunnel engineers to do their work, including everything from generalist platforms like AutoCAD to specialist software from providers like Rocscience and Bentley. Rocscience provides a wide suite of software for civil, mining, and geotechnical engineering, whereas Bentley focuses on infrastructure engineering.

Theodora specifically referenced Rocscience’s RS2 and RS3, which are used for modeling soil, rock, groundwater, and ground support in 2D and 3D respectively, and Plaxis, a geotechnical software solution that also offers finite element modeling, including the analysis of tunnels, dams, and foundations.

This software is often very expensive. For example, many of Rocscience’s software offerings are offered as a one-time license purchase, with RS3 priced at $13,795 per seat. This creates a situation where smaller tunneling projects often do not budget for much pricier 3D modeling solutions, despite the increased complexity and planning demands of the average modern project.

Moreover, this specialized software often requires years of training and hands-on experience, and still requires engineers who are using it to exercise a lot of judgment. As Theodora put it, existing software solutions will “generally not tell you” if its output is correct or likely to cause a problem. It still requires the expertise of the engineer to evaluate if, for example, a tunnel being designed is likely to function properly or collapse.

Theodora also said that many tunnel engineers – who tend to be older – prefer manual drawing processes and can be reticent to follow technological trends, but that this is changing with time.

3. The tunneling industry deals with problems of information transfer and access.

The number one pain point in tunnel engineering, Theodora says, is politics. Projects can be delayed or halted due to funding issues or changing priorities from the client, many of whom are governments or municipalities. This uncertainty often translates into a significant amount of paperwork and administrative tasks, diverting attention from the core design work.

Theodora said has been involved in projects that were paused and later resumed by a different company. These interruptions pose challenges in maintaining project continuity and can result in the loss of valuable expertise and data. Engineers may move on to other projects or even retire, and the new team might not have access to the tacit knowledge acquired during the initial phases of the project.

This issue is compounded by the difficulty of getting the right information in the first place. Many tunnels – like subways, for example – are built in heavily congested urban areas, which often contain extensive pre-existing underground infrastructure like power, water pipes, and sewage lines. Often, knowledge about what exactly is underneath any given patch of urban land is contained in disparate and unreliable sources. Theodora describes being supplied information from clients in the form of decades-old hand-drawn documents, which may not be accurate within the expected tolerances of a modern engineering project.

Our full conversation with Theodora

Source: Washington State Dept of Transportation

Let’s start by introducing yourself and how you got into becoming a tunnel engineer.

My name is Thedora or Dorina. I'm Greek. I was born there, I studied there and then I continued my studies in the US — and I'm still here. I studied mining engineering, and initially I thought I wanted to go towards the oil and gas industry, but I really liked tunneling because we had a lot of courses related to that.

So I wanted to mix my studies with civil engineering to cover what was missing in terms of a technical background. So I did a masters degree specifically in tunneling. That was again in Greece, and then I came to the US and started civil engineering. It was geotechnical and earthquake [engineering], basically.

And then I found my first job, which was in tunneling. So I've been in this industry since 2016. I design tunnels, and do project management for large infrastructure projects in the water and transit sectors. So basically anything underground, be it a subway, station, water tunnel — you name it. Nothing above grade!

Talk a little about the education side. Is tunneling a specific discipline in civil engineering? If you want to become a tunnel engineer, is it a specific track that you go through in your degree or courses?

It kind of depends where you study, because there aren't many schools that offer this expertise.

You need to know a lot about geology and how the ground behaves. This is what most people lack knowledge of: how the rock interacts when you excavate it and when you want to build in it. There are many courses related to rock mechanics and rock behavior. It touches on civil engineering and also geology. It's not very easy to find a relevant course or graduate program for that.

In the US there are some schools that focus on it. Like the Colorado School of Mines, which offers a lot of laboratory work. But it requires a lot of hands-on experience. When I studied, the professors used to organize a lot of field trips. They’d get very passionate about it — “You have to go out and see the mountains, and you have to touch them!”

But it’s important to get that experience, because the geology in one spot might differ from the geology just ten meters away. All underground projects are different. It's not something that you can copy paste — like a building, where you do it once and you can be very confident that you will be successful again.

You might have done dozens of tunneling projects, but your next one fails because you weren't careful enough to figure out exactly what the ground conditions were.

Let’s talk about building tunnels. Start with the basics: what are the different reasons a tunnel gets built?

Well, it might be for a subway. It might be a road tunnel. For trains, for cars, for water. A lot of sewer tunnels are being built. It’s not only the tunnels themselves — it's also the shafts that are part of underground construction. Many tunnels are connected to shafts.

You might also have an underground facility, like parking, or a part of a building that goes underground. We don’t usually do that kind of work, unless it's a very large development that has something critical where they would need input from a tunneling person. If it’s just a simple building which features an underground part, the usual developers can do that.

What are the considerations you need to take into account when building a tunnel?

Usually, these are public projects, and very big ones. So you need to secure the funding first. This usually takes months or years. You can never know — you might be working on a project, and then it might get paused and start again after 10 years.

We get the direction from the client. Let’s say there’s a subway — the client might tell you that they need a new line that will connect downtown to the airport. As a designer, you figure out how you will do that. I would start with the alignment, to figure out how you would start the excavation, because if it's in a congested urban area you need to make sure you get all the permits and there is enough space to bring all the equipment.

Usually underground you follow an existing street. You can’t really go underneath buildings or wherever you want. If there is a street, you can go underneath it and follow its alignment. If you need to turn, then you need to get some sort of permit. Sometimes the client will tell you how deep you can go or how shallow you can go. Deeper is easier. If it's a shallow tunnel, you have to figure out what existing utilities are buried under the street and whether there are buildings you need to avoid.

Sometimes you may need to add some measures to protect the existing buildings, or to relocate utilities. For example, if there’s a water line, you might need to move it a few meters to the left or right depending on how close it comes to the tunnel.

Are you usually building in urban areas like underneath cities, or do you also build in more remote, less congested areas?

Usually all the subways are in very congested areas. The water tunnels can be easier, because you might be underneath a river or somewhere else where you don’t have to deal with buildings.

The constraints are where the tunnel approaches the surface, because you need to have a portion that is kind of an open excavation, because at some point the tunnel comes up and meets the grade elevation. If there is an existing train line, it will connect to that line. This is where it gets complicated.

On the shallow tunnel problem: is there a centralized database or some other way where you can view existing utilities, or assemble information about what might be below ground?

Usually the client provides us that information. If there's a recent project in that area, and they have created boreholes, that would give you an insight too. But it's not like you can just Google and find it.

Sometimes this information is very old, and you might get drawings and blueprints from 50 or 100 years ago. In that case, you're often not exactly sure the pipe is exactly where the document says it is or a few feet away. They’ll often do some local excavations, or they do some surveying, and then you kind of map everything. Nowadays, we do everything in 3D. So you just put everything in the model, and then you know where things are.

Does that information go anywhere afterward?

It’s not public information. But if there’s another project in the area in the future, they’d probably be able to get it.

On the subject of your 3D renders: what are the primary set of tools you use — be it software or hardware?

This industry is kind of afraid to adapt to the latest technological advances, I would say, because many people are very old school and they prefer to do things by hand. I don't know why. It’s also a field that requires a lot of experience. Most of the people working in this field are over 60 years old. If you tell them we're doing everything in 3D now, they don't really like it.

But projects are so demanding nowadays that you can’t really rely on drawings and CAD. If something changes, you need to manually change all these drawings, which is a headache. When I started in 2016, we were working on a proposal for a project, and we had thousands of drawings to deliver. We were working in 2D then, and every day something was changing, and then you have to change all of these drawings. Then at some point, you will inevitably miss something because you remember, “Oh yeah, this changed and it’s now one meter bigger.” It’s a mess.

Another time we won a project and it was a requirement to do everything in BIM (building information modeling). So we were using Revit and all the disciplines were working together. You had the civil engineers, the architects, as well as electrical, mechanical and structural people – everyone had their own model, but they were all linked together. You could see if there is a problem or if something clashed. The contractor also has access, so they can see what is going on and if something is not constructible, or if there is a safety issue.

So, something like that can be really helpful with identifying issues.

So these tools are out there, but there's a little bit of slowness in takeup — is that right?

That's right, at least for the drawing part. There’s also software that we use for the analysis to design the tunnel.

There’s many different types of software for these purposes. There could be one for geotechnical purposes to control the ground and check the stresses and the forces on the structure and then another for the structural engineering part. So if you have an underground station, you would need to design the columns, the beams, and everything else in it. So there is a bunch of different software that apply in these cases.

Many of these software products are from Bentley. For tunnels, we usually prefer the Rocscience platform. They have many different types of software, working in both 2D and 3D.

It starts with the very basics of rock mechanics. You can get information about the properties of the rock, and then you can do settlements, you can design a dam, you can design underground tunnels. Then they have a program called RS2, which is for designing tunnels in 2D, and then there is also an RS3 which is in 3D. Then there is Plaxis — that is also 2D and 3D and was recently bought by Bentley.

And these are all different platforms that you have to learn. There is no single solution here for all your tunneling needs?

No, it's specific software. Usually, you need to work on them for years to understand them.

The problem is that you need to be aware of the results that you will get, because the software will generally not tell you if it's correct or if it's wrong. For example, you might want to design a tunnel, and it tells you it has a settlement of 10 centimeters. Then you have to use your critical thinking to determine if that’s fine or if it’s going to be a problem. The software won’t tell you if it’s going to collapse, for example.

That's why you need to have a lot of experience to figure out what exactly you're doing, because it needs a lot of input. Unfortunately, it needs many years of training and use.

So, you’re involved in the design and surveying of a tunnel. Once that’s out of your hands, are you much involved in the construction process, when there are workers building and excavating the tunnel?

I work in a consulting firm, and when you take on the design, you also provide support during construction. So you get to visit the site and to see what exactly they're doing. Depending on the contract, sometimes the contractor needs to follow exactly the designers work — so you need to be there to make sure that they're doing what they’re supposed to do.

Are there any problems that come up at this time that you need to address?

Yes, sometimes there's water that you haven't accounted for, and you need to think on the spot and provide a solution. Sometimes it's a lot of water, so you might need to demolish and rebuild.

Other times you might not have evaluated the ground properly. If you have made a mistakelike, the boring machine might get stuck. If it gets stuck, you can't really take it out, and you lose millions of dollars.

In the time you have spent in the industry, have you observed any changes?

In terms of design, nothing is different. In terms of software: everyone wants 3D product now. Whether or not you do depends on the size of the project. If it’s a large project, they will provide the budget for it. If it’s a smaller local project — like an excavation for a shaft — then maybe not.

Software is expensive. For example, we were using software that can map alignment in a tunnel, and it gives you a 3D view of it. It’s very specific software and very expensive — they give you a license for only one person. But you don’t really need to train 50 people to do it. On the other hand, something like Revit or AutoCAD — which we use to produce drawings — is usually provided by companies for free.

Have you observed any hardware changes with regard to drilling tunnels, and do you take that into account? Anything that might change the economics of tunnel construction?

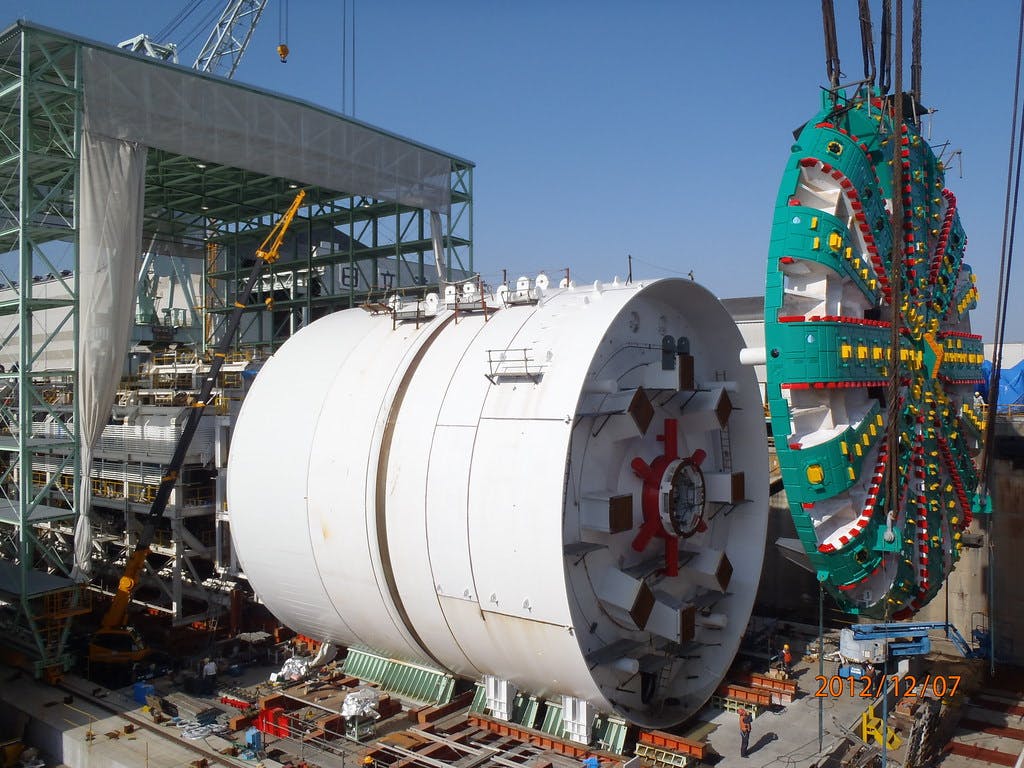

They make larger machines now. Every year these companies make some presentations, and they show you what they have fixed or improved. Now they have very large diameter machines, and they can also make them operate at very deep and sharp angles, whereas previously you could only go horizontally — maybe at a maximum of 4 or 5% grade.

Usually, these are used in remote areas, if you're excavating a mountain or something like that. If you don't have any restrictions, then these are very beneficial. You wouldn’t use it for a train tunnel, for example, which has a maximum slope which is quite specific. But if it’s for water or a diversion tunnel or something like that, you can use these machines.

The other advances I see are in materials being improved to reduce the carbon footprint. So we see moves to replace concrete and steel with newer materials, like carbon fiber and polymers. That’s where the industry is heading.

Are there any major pain points in your job beyond what you’ve already described?

A lot of politics, especially when it involves public projects. It’s always uncertain if you start working on a project whether it's going to be stopped because of funding issues or because the client changes their mind. Unfortunately, instead of doing design, you do a lot of paperwork and bureaucratic, administrative stuff.

It's also not very easy to find people. There aren't many people who do this work. And we're usually scattered around the world. In my previous company, we had people all over the US. We were not in the same office. We had people in California, we had people in Boston, we had people in New York. It’s rare you can find 50 people and have them all in one office.

In this field, you will either see entry-level roles or ones for someone who has 20+ years of experience, there is usually nothing in between. Many people choose to stay in academia. You also lose a large percentage of people who have the technical background and who might join as a tunnel person, but then go and do something else when there are no tunnel jobs and end up pursuing a different path.

In cases where a job does stop and start as you described — sometimes for years — how do you keep track of all the information? Where does that information live in the meantime, regarding all the things in progress when the project was paused?

The thing is that it may start again and it may be a different company that gets to work on it. Usually, we'll stop when it's in the design phase or if it's in a preliminary design phase. At that point, it’s usually about 30% of the work which is not very detailed and then subject to complete change.

I'll give you an example. I'm working on a project now that I used to work with my previous company when I joined in 2016.

So we did the 30%, and then the client decided that they didn't want to proceed, which was fine. And then it started again now, and my current company got the job. They got all the information from a previous company, basically. You get all the deliverables and whatever data they had before. You're not going to get anything people were working on that they didn't release. And then you continue based on that.

Whatever is needed — like the utilities or information about existing buildings and previous work, you’ll get either from the client or some other public entity.

Takeaways for founders

From our conversation with Theodora, there are several plausible opportunities for founders to explore within tunnel engineering specifically, as well as other large infrastructure and engineering projects:

Disrupting the existing software market

Verticalized design and planning software in infrastructure engineering is dominated by long-standing firms and is heavily task-specific. Rocscience, for example, lists 20 different software applications on its website, each for specifically defined tasks. There could be an opportunity for a modern, collaborative platform that is more suited for a new generation of engineers. Intuitive, easy-to-learn software could also help bridge the generational gap in this field.

Tackling the information problem

As Theodora described it, necessary information for subterranean construction is often outdated and unreliable. There could be scope for a new kind of information repository for major urban infrastructure in the US and beyond, drawing upon publicly available information in conjunction with sensor and survey data, predictive models, or some other solution. Additionally, information continuity in large, complex public infrastructure projects is often severely lacking. Piecing together these disparate information sources could create immense value for underground construction in particular and public works in general.

Enabling knowledge transfer

One of the common issues we’ve surfaced across the interviews we’ve conducted so far is that of knowledge transfer in the real-world economy. The full range of skills needed for cross-disciplinary trades such as tunnel engineering, commercial piloting, or lineworking are rarely taught in schools and are often acquired on the job. With many of these professions facing an aging workforce, the problem of knowledge loss when older generations retire becomes increasingly pressing. A tech-enabled way to more easily capture, retain, and transfer that professional knowledge would likely create a great deal of value.

Disclosure: Nothing presented within this article is intended to constitute legal, business, investment or tax advice, and under no circumstances should any information provided herein be used or considered as an offer to sell or a solicitation of an offer to buy an interest in any investment fund managed by Contrary LLC (“Contrary”) nor does such information constitute an offer to provide investment advisory services. Information provided reflects Contrary’s views as of a time, whereby such views are subject to change at any point and Contrary shall not be obligated to provide notice of any change. Companies mentioned in this article may be a representative sample of portfolio companies in which Contrary has invested in which the author believes such companies fit the objective criteria stated in commentary, which do not reflect all investments made by Contrary. No assumptions should be made that investments listed above were or will be profitable. Due to various risks and uncertainties, actual events, results or the actual experience may differ materially from those reflected or contemplated in these statements. Nothing contained in this article may be relied upon as a guarantee or assurance as to the future success of any particular company. Past performance is not indicative of future results. A list of investments made by Contrary (excluding investments for which the issuer has not provided permission for Contrary to disclose publicly, Fund of Fund investments and investments in which total invested capital is no more than $50,000) is available at www.contrary.com/investments.

Certain information contained in here has been obtained from third-party sources, including from portfolio companies of funds managed by Contrary. While taken from sources believed to be reliable, Contrary has not independently verified such information and makes no representations about the enduring accuracy of the information or its appropriateness for a given situation. Charts and graphs provided within are for informational purposes solely and should not be relied upon when making any investment decision. Please see www.contrary.com/legal for additional important information.