Imposing buildings are an emblem of modern cityscapes. It seems that with each passing year the tallest skyscrapers in places like Manhattan and Shanghai reach ever higher into the clouds.

However, the rules of structural engineering assert that there are limits to how tall buildings can get. There are no such limits when we build in the other direction — down. The Burj Khalifa, the tallest building on Earth, stands at around 2,700 feet tall. One of the deepest holes ever dug, the Kola Superdeep Borehole (a scientific drilling experiment carried out by the Soviet Union in the 70s) is over 15 Burj Khalifas in depth.

There’s a lot of untapped potential with underground construction. And in fact, as the global population has grown and concentrated in dense urban centers, figures like Elon Musk have argued that it’s high time we stop thinking about our civilization in two-dimensional terms — existing on the surface of the Earth — and begin thinking in three dimensions.

If everything from transportation networks to utility infrastructure were to be expanded underground, it would help solve problems endemic to modern cities like traffic congestion.

Large, powerful boring machines capable of producing underground structures have been available in their modern form since the 1970s. Unfortunately, that was also the last time the tunneling industry saw any significant innovations. Since then, the costs of digging and building underground have skyrocketed — particularly in the United States, where laying down just one mile of underground tunnel can cost upwards of a billion dollars, the highest price tag in the world. As our need for more sophisticated underground construction has grown, the costs of doing so have ballooned in tandem.

The Big American Tunneling Slump

New infrastructure projects in the United States are often associated with exorbitant costs and excessive build times. A simple extension to the Manhattan subway system resulted in the most expensive subway project in the world. It ran up a bill of $2.5 billion per mile, five times more than what it would’ve cost to build the same thing in Paris.

Or take the nightmarish history of ‘The Big Dig’. This project, which aimed to build new underwater tunnels connecting the banks of Boston, became the most expensive highway project in the United States. An initial budget of $2.8 billion ballooned to $22 billion, a cost that probably won’t be fully paid until 2038. Construction for The Big Dig began in 1991, and was scheduled to be completed by 1998. Instead, the project was finally completed on December 31st, 2007 — a whole decade behind schedule.

Although such issues have plagued American infrastructure projects in recent decades, the US didn’t seem to have much of a problem building its extensive system of highways and corresponding tunnels during the 1950s and 1960s. In fact, the list of impressive and complex tunnels built across America is extensive, even if most of those tunnels were constructed half a century ago. It is only lately that building new infrastructure in the US has become so difficult, and it is now more expensive to do so here than anywhere else in the world.

However, this isn’t the case universally. Other countries, like Great Britain and others across Europe, often caricatured as technological laggards, are eagerly embarking on all kinds of new underground transportation projects in 2023. For example, in 2022, London unveiled its new Crossrail project, which will expand London’s rail capacity by 10% and carry 200 million people a year. Though this project, too, was criticized for delayed construction and a higher-than-expected budget.

This tunnel, was actually constructed beneath another London tunnel — the Mail Rail. Between the years of 1927 and 2003, the UK Post Office delivered mail to customers using a network of underground tunnels and rail carts. Since 2003, it’s become an underground laboratory for Cambridge engineering students studying the effects that building another tunnel beneath the Mail Rail line would have on the Mail Rail’s structural soundness. So far, so good it seems. And if that’s not all, in 2026, Great Britain will embark on building its longest road tunnel yet: the Lower Thames Crossing.

All across Europe and Asia, tunneling projects to expand roadways, replace leaky old utility pipes, or redirect flows of water are making headway. All this makes the question of America’s difficulty in building new underground constructions of its own even more puzzling. What gives?

A Brief History of Tunneling

Underground construction is actually an ancient practice. As far as we know, the first tunnel ever built was the Euphrates Tunnel in Mesopotamia. This was likely constructed sometime around 2170 BC to connect the two sides of Babylon beneath the Euphrates River.

Although the tunnel has never been found, there are accounts of the tunnel in the writings of the ancient Greek historian Diodorus. Diodorus wrote his account much later, in 50 BC, but he described with great detail the means by which the Babylonians dammed the river, dug the tunnel, lined its walls with brick and bitumen to secure and waterproof it, then covered it up to restore the flow of the river.

Another sub-sea tunnel of such ambition was not built for many thousands of years hence, but many impressive underground structures were still embarked upon in the intervening period. Take the Valley of the Kings, a massive system of underground tombs consisting of hundreds of chambers built amid limestone, shale and chalk used to bury the pharaohs and high-ranking officials of ancient Egypt. Or take the ancient Persians, who built tunnels over 2,700 years ago, many of which are still in use today. Romans built tunnels too, to divert rivers and allow passage through treacherous terrain. What is perhaps most amazing about all these passages and constructions is that they were built without any formal knowledge of the advanced math or physics we use in construction today. All that was required was a combination of rigorous practicality and intuition, passed down through time, from master to apprentice. Their solutions to hard problems, like carving through rock, were ingenious. At times they used the technique of fire-quenching, which heats the rock and rapidly cools it with cold water to make it crack. Of course, all of these constructions were built by armies of thousands of workers who chiseled away at stone for days on end.

The fall of the Roman Empire put an end to massive underground construction. It was not possible to organize the extraordinary labor force to take on such an effort anymore and it would take centuries for tunneling to become economical again.

The invention of gunpowder in 1627 and the rise of explosives more generally, made it possible to unleash a massive amount of force very quickly. Hard rock didn’t need to be fire-quenched or chiseled away a few chips at a time anymore, it could just be blasted to bits. Simply by drilling a small opening in a rock, packing it tightly with a lot of gunpowder, attaching a fuse, and lighting it, massive amounts of rock could be removed, greatly accelerating the tunneling process.

After the invention of gunpowder and dynamite, throughout the 1800s, Europe became obsessed with blasting away mountains and rock faces to carve new train paths through the Alps, and through the rocky regions of England, Switzerland and more.

However, even after clearing through rock became easier, there were still many challenges that came with tunnel construction. Four thousand years after the Babylonians supposedly built a half-mile-long tunnel beneath the Euphrates, the English were having a great deal of trouble doing something similar in the mid-1800s. At that time, there was a growing desire to create a tunnel to connect both sides of London beneath the Thames River. Numerous attempts at doing so ended in failure. The issue stemmed from the fact that engineers would run into soft clay and quicksand, which kept flooding out or collapsing the excavation attempts being made.

In 1823, however, an intrepid engineer named Marc Brunel produced a new plan to tunnel beneath the Thames River using a new tunneling system he patented called a “tunneling shield”. The idea was to bore a large hole in one bank of the Thames which would reach the intended depth of the tunnel. Inside the hole, a multi-level structure would be built, facing the wall to be excavated, with compartments created for numerous workers who would carve out the wall face manually. The excavated dirt would then be removed via the shaft, and while the tunnel bored further beneath the Thames, additional workers would secure the structure of the tunnel by laying brick around it in the rear. This way, the tunnel could be dug and structurally secured simultaneously. The digging was slow because it was manual, but it made tunneling under a river possible. The Thames River Tunnel took 18 years to complete and was finally opened in 1843.

Source: Londonist

Tunnel-mania consumed Europe after this. In 1863, London began building the world’s first underground metro. Much of it was constructed using another tunneling technique called cut-and-cover. With this technique, an open trench was dug spanning the length of the metro line, structural supports were added, and then the tunnel was covered up!

This open air technique was much preferred to the fully underground digging, which had very poor circulation combined with the risk of leakage of noxious and flammable fumes which blighted much of the Thames tunnel construction process. While much of Europe and New York, were in the process of digging up their cities to install new underground transportation, they took the opportunity to install subterranean sewage systems alongside the new subterranean transit system. So, following the construction of most modern subways across London, Paris, Budapest, and New York, many of today’s modern sewage systems were also built.

Source: The History Press

As tunnel construction continued, attempts were made to automate boring at the face of the tunnel using pneumatic drills. The first such machine was Henri Maus’s boring machine created in 1848. This was heavily inspired by Brunel’s shielding structure, but instead of placing men at the tunnel face, Maus replaced them with rows and rows of drills.

Tunnel boring machines were expensive to produce, and ultimately were not capable of cutting through rock. Remarkably, it would take another hundred years for this to become possible.

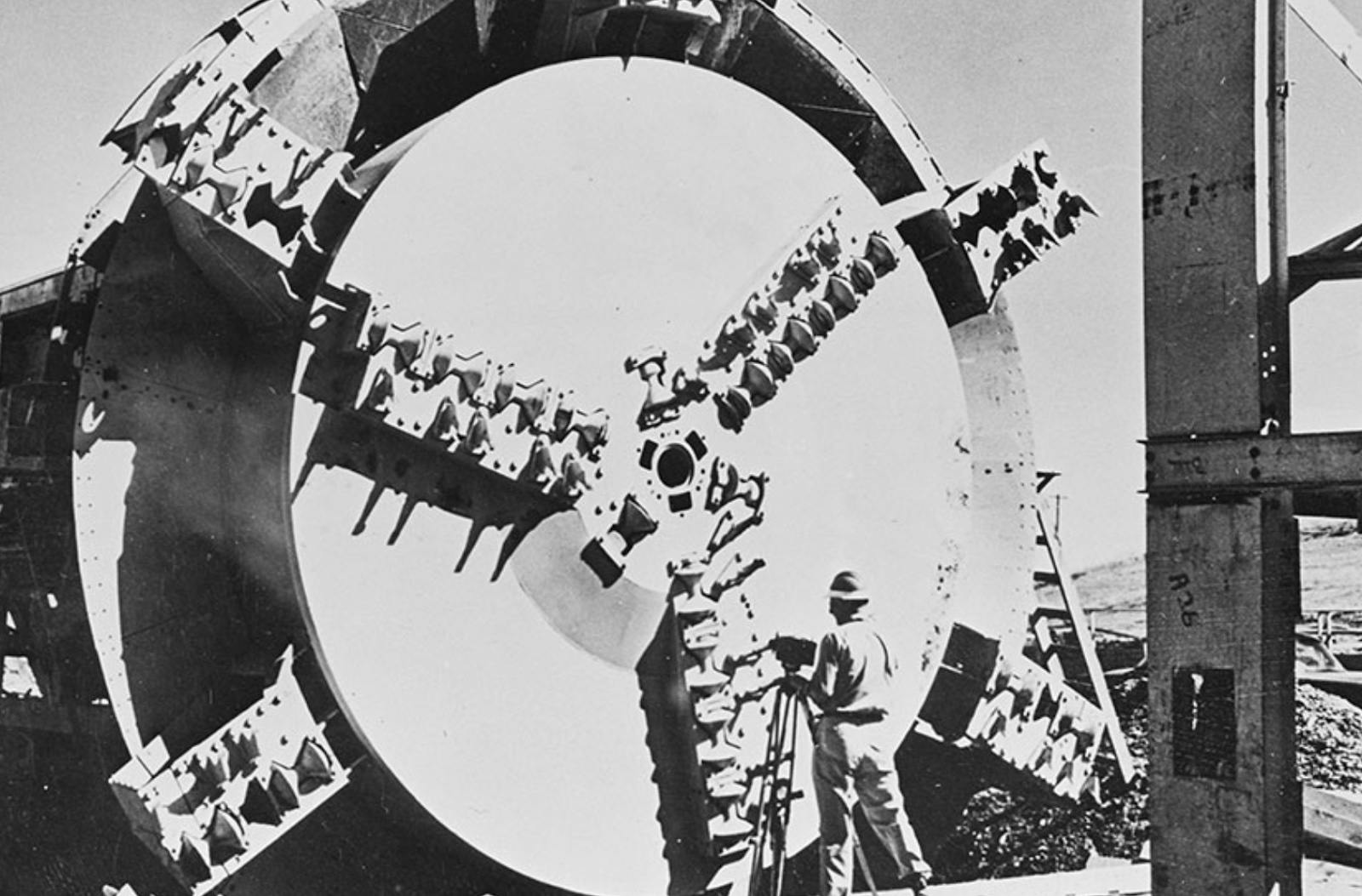

In 1952, an American engineer James Robbins was the first to design a tunnel boring machine that used serrated components called drag bits alongside sharp disc cutters on the machine’s cutter head. The components worked in unison, such that while the drag bits grooved the rock, the cutters could break off parts of the stone. The machine ended up being used to build the Oahe Dam in South Dakota. Since then, Robbins started one of the most prominent boring companies still producing tunnel boring machines today.

Source: Robbins TBM

How Tunnel Boring Works

Not a whole lot separates the tunnel boring machines of today from the one designed by Robbins in the ‘50s. Different technical adjustments were made to the cutterhead allowing it to bore through different types of soil, however the overall operation of the boring machines remains unchanged. Though to be a little bit more precise, let’s break down exactly what that operation looks like:

1. Surveying

Before any digging begins, teams must first get a firm sense of what they will be boring through. The type of material beneath the earth will not only determine whether a tunnel may be dug, but also what kind of tunnel boring machine (TBM) will be needed, if one will be needed at all.

One of the most difficult things about underground construction is never being 100% certain of what you’ll find underground. That’s why de-risking with extensive testing and surveying ahead of time is crucial. Geotechnical surveys to assess the composition of the rock or soil are conducted by drilling boreholes to extract and analyze soil samples. Ground penetrating radar is also used to produce images of the subsurface and detect unexpected voids, caverns, or other structural qualities of the subsurface.

If digging through soft or granular soil, slurry shield TBMs may be used which pump a thickening agent called a slurry ahead of the cutter to help maintain the structure of the borehole as it moves through the watery and sandy soil. Clay-based or silt-like soils might use an Earth Pressure Balance TBM, which tries to balance pressure from the earth with pressure from the boring machine as it digs. There are also Mixshield TBMs that handle heterogenous ground and Hard Rock TBMs which handle very tough rock formations.

2. Excavation

Once the surveying is complete, TBMs are usually custom-built for the specific dig project. In most cases, they’re fully built and tested at a factory before being disassembled and shipped to the project site where they are reconstructed.

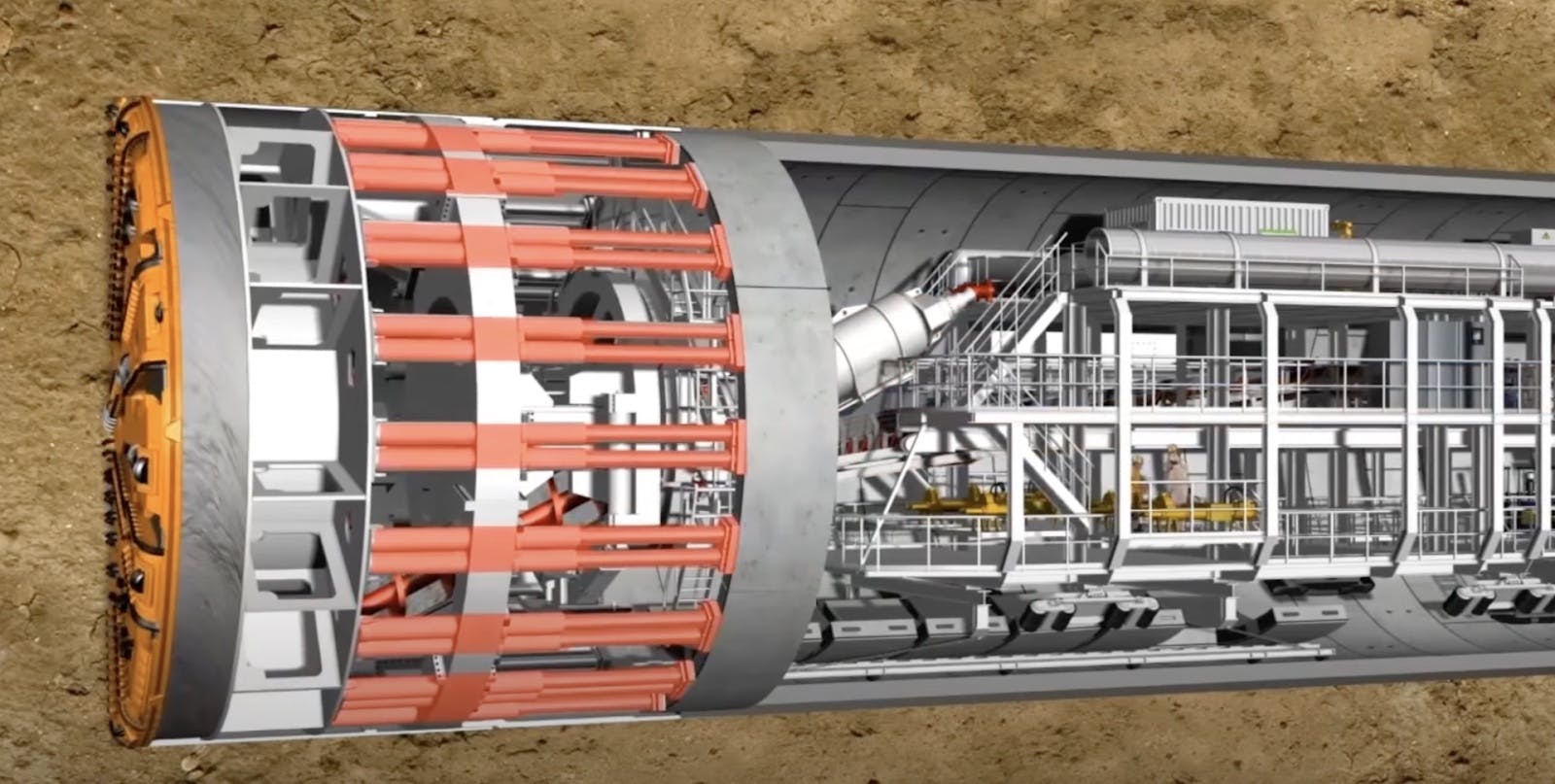

After this, an access shaft is dug, into which the TBM is carefully lowered. The most important part to get right at this stage is correct orientation of the TBM. Different tools from inclinometers to even GPS are used to ensure TBMs are oriented correctly in the digging process. Once in place, the cutting face will begin rotating and carving through soil. The TBM has extending hydraulic arms which push on the cutter head with a pressure of 400 bar, roughly 400 times the atmospheric pressure at sea level.

Source: Herrenknecht AG

As soil is excavated, it falls off the face of the cutter and is collected by a series of conveyer belts which carry it out of the tunnel. The entire structure of the TBM is held inside of a giant cylindrical shell which ensures the structural integrity of the front of the tunnel as the cutterhead carves the path ahead.

Source: Tunneling Online

3. Structural lining

Also onboard the TBM are precisely shaped lining segments molded out of concrete on-site. As the TBM advances further in the tunnel, the lining segments are picked up by an erector inside the TBM and installed inside the TBM’s cylindrical shell. The segments are interlocked, creating a sturdy and durable structure that distributes the load and pressure from the surrounding soil. Then, the hydraulic thrusters push off against the newly installed concrete segments to advance forward, leaving a completed concrete tunnel ring behind it.

Though the TBM works faster than an army of men with pick axes, it still doesn’t work very fast. Modern TBMs advance at a rate of 15 meters per day on average, which is an improvement over Brunel’s shield tunneling method which advanced at an average of 4 inches per day, but is still some 14 times slower than a snail’s pace.

A further inefficiency is the fact that TBMs actually stop digging while the structural linings are being installed along the sides. It does this to ensure that the structural linings are secure before moving forward, but it also means that TBMs are not digging for a lot of the time they are underground.

Though there are many complex issues plaguing the construction of tunnels today — these are some of the lowest-hanging fruit when it comes to improving TBM performance and cost efficiency.

The Future of Digging

Enter Elon Musk. Upon becoming outraged by Los Angeles traffic while traveling to SpaceX headquarters, he began wondering why it wasn’t possible to expand Los Angeles’ travel infrastructure underground. Slow and expensive boring machines were the problem. In 2017, The Boring Company was started as the solution.

The main objectives of The Boring Company were basically twofold — to increase the power and speed of traditional boring machines, and to make the process of lining the tunnel happen simultaneously as the machine digs.

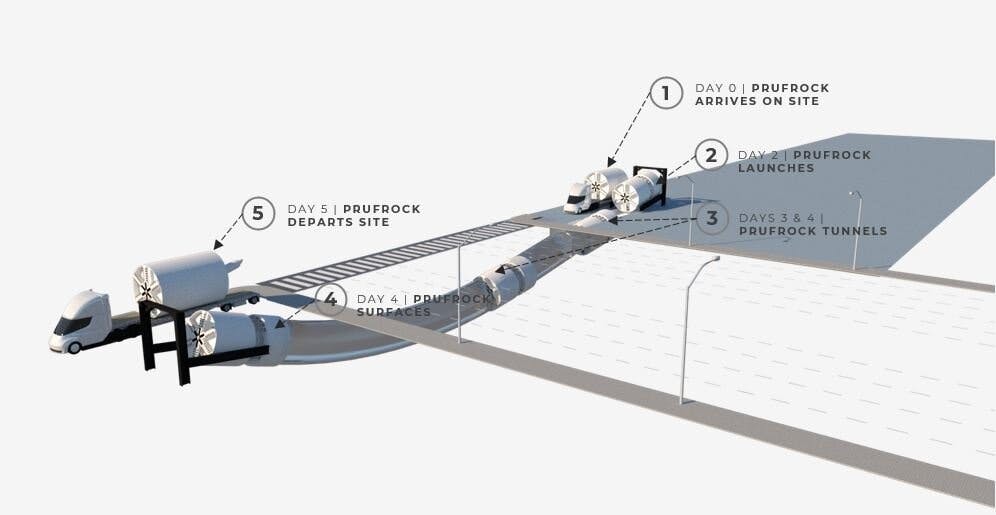

The company’s boring machines, the Prufrock models, are already capable of digging faster than traditional TBMs. The Prufrock-2 digs up to a mile per week. Its successor, the Prufrock-3 is expected to dig at a rate of seven miles per day. Another innovation of the Prufrock is “porpoising” — rather than digging a hole and lowering the TBM into it before it can get to work, the Prufrock can just bore straight into the earth to the desired depth from the surface. Then, once it’s done digging the tunnel, it resurfaces and can be collected.

Source: The Boring Company

Elon Musk loves the concept of re-usability, and tunnel construction is another sector (in addition to space) where re-usability could massively decrease costs. In many projects, it is so costly to remove the TBM from its tunnel that many companies just leave it below ground once the tunnel is constructed. With porpoising, The Boring Company is making TBMs reusable, lowering the cost of digging.

In short, The Boring Company isn’t completely re-imagining tunnel digging, just trimming the fat by lowering costs while also perfecting existing techniques to allow for faster digging. At the same time as this is being pursued, however, there are a few endeavors attempting to rethink the underground construction process from the bottom up. One such company is Hypertunnel, a British tunneling startup founded in 2018.

Hypertunnel envisions a fully autonomous system composed of swarming robots that can drill the tunnel outline and set its external structure using 3D printed material — eliminating the need for a large boring machine that pulverizes the ground. The idea is that once this tunnel structure is set, the earth beneath it will simply break off and be removed. The goal, however, is that this technology could be used to build much more complicated underground structures than what is currently feasible through boring machines alone. The company is currently working on prototyping this technique, but it seems apparent that a technique like this will probably only work for softer soils.

Digging through hard rock is still a big issue for tunneling, and many kinds of hard rock like granite and quartzite are challenging even for TBMs to bore through. Companies like Earth Grid and Petra are trying varied techniques from plasma torches to superheated fluids which can crack tough rock.

The prospects of building complex structures underground, or terraforming more broadly are both woefully under-explored merely because we’re not that good at building underground. However, the re-ignited interest in finding better ways to bore and build is heartening. Whether it’s three-dimensional highway structures that lay in the future, or easily accessible and well-organized utility tunnels which can be readily accessed by technicians, the prospects of building underground holds tremendous promise.

Disclosure: Nothing presented within this article is intended to constitute legal, business, investment or tax advice, and under no circumstances should any information provided herein be used or considered as an offer to sell or a solicitation of an offer to buy an interest in any investment fund managed by Contrary LLC (“Contrary”) nor does such information constitute an offer to provide investment advisory services. Information provided reflects Contrary’s views as of a time, whereby such views are subject to change at any point and Contrary shall not be obligated to provide notice of any change. Companies mentioned in this article may be a representative sample of portfolio companies in which Contrary has invested in which the author believes such companies fit the objective criteria stated in commentary, which do not reflect all investments made by Contrary. No assumptions should be made that investments listed above were or will be profitable. Due to various risks and uncertainties, actual events, results or the actual experience may differ materially from those reflected or contemplated in these statements. Nothing contained in this article may be relied upon as a guarantee or assurance as to the future success of any particular company. Past performance is not indicative of future results. A list of investments made by Contrary (excluding investments for which the issuer has not provided permission for Contrary to disclose publicly, Fund of Fund investments and investments in which total invested capital is no more than $50,000) is available at www.contrary.com/investments.

Certain information contained in here has been obtained from third-party sources, including from portfolio companies of funds managed by Contrary. While taken from sources believed to be reliable, Contrary has not independently verified such information and makes no representations about the enduring accuracy of the information or its appropriateness for a given situation. Charts and graphs provided within are for informational purposes solely and should not be relied upon when making any investment decision. Please see www.contrary.com/legal for additional important information.