Manufacturing, broadly speaking, is an industry that turns raw materials into finished goods.

Given the diversity of products exchanged in our economy, we might imagine that there are as many different ways of making things as there are goods sold. However, the reality is rather different.

The world of mass manufacturing is organized around a handful of key technologies and machines capable of shaping material into particular forms. It is these machines and their limitations which dictate the geometries and materials of all manufactured goods around us.

However, it is not just product design which is dictated by manufacturing technologies. The shape of the entire production process itself, which informs the configuration of modern supply chains and even firm structure, ultimately stems from the kinds of machines we have available to perform essential manufacturing tasks. It is for this reason that the kinds of manufacturing technologies used are supremely important. They play a critical part in determining our economic structures.

The current manufacturing paradigm is marked by complex and opaque supply chains and convoluted coordination processes. Though decentralizing and outsourcing production has allowed us to decrease the cost of producing goods, it has also constrained the design aspirations of potential products and imposed a ceiling on their complexity.

However, a new manufacturing paradigm is now arising with the potential to totally reorganize how and where manufactured goods are produced. Advanced and additive manufacturing technologies are evolving from hobbyist tools to critical components of mass production. Though there are still many challenges for additive manufacturing technologies like metal 3D printers to solve, they are increasingly displaying promise of the kind of flexibility, control, and design freedom manufacturing process engineers have been dreaming of for decades.

The State of Modern Manufacturing

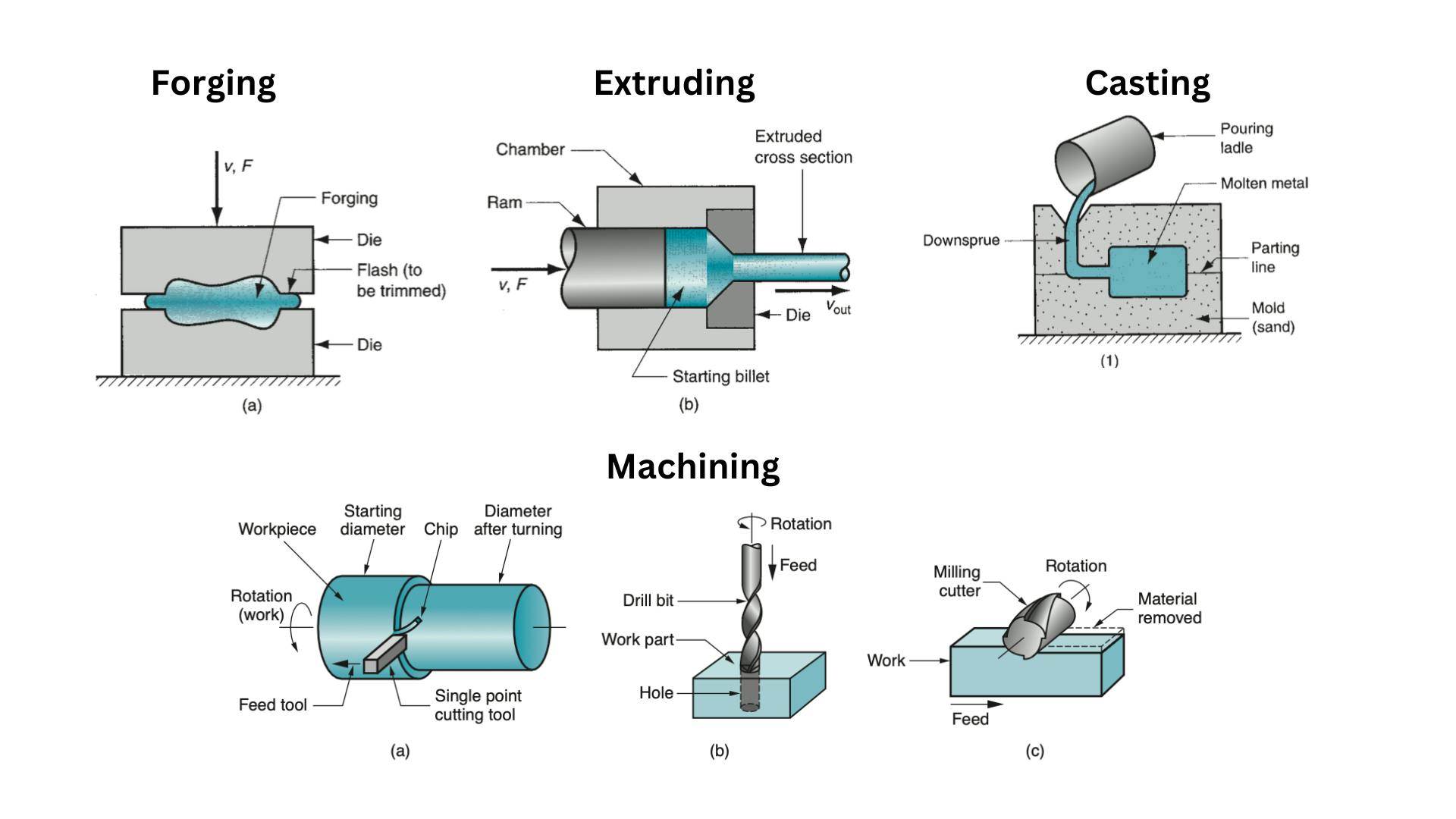

The present manufacturing framework relies on a philosophy of subtraction. Essentially, this means that manufacturing plants turn raw materials into parts by shaping them or chiseling them down, as a sculptor would a piece of clay or marble, until the desired part is achieved.

There are really only a handful of standardized processes used to shape materials today. These are:

- Forge hammers, which repeatedly apply a massive amount of force on metal through a specially designed die to either stamp the metal or deform it into the desired shape.

- Presses, which apply a consistent amount of force onto material through a die to forge it or extrude it through a specialty piece into the required part.

- Molds, where molten material (typically metal) is poured into a cast until it solidifies into the right shape.

- Machine tools, the most historic and critical production tools, which can turn and cut, drill or mill materials from wood to metal.

Source: Fundamentals of Modern Manufacturing

Some combination of these techniques is used to produce all of the manufactured products in the economy. To produce specific components, each technique requires the use of a custom-machined piece, called a die. In the case of a forge hammer or press, the die is inserted into the machine, such that the raw material will be deformed according to the die’s direction. The image below shows a die designed to progressively stamp a Toyota Logo into sheet metal.

Source: Glenn McKechnie

Though it might seem that manufacturing processes are sufficiently general and automated, this is not always the case. Though modern factories now possess computer-guided machining tools called computer numerical control (CNC) machines, capable of cutting individual pieces according to digital specifications, such machines can only produce one piece at a time and so are not suitable for truly mass-scale part production. However, CNC machines are now often used to produce the dies needed to make large batches of identical manufactured parts.

Despite the fact that the CNC machines are guided by a computer, they still require near complete human oversight to translate die configurations into optimal cutting instructions.

Thus, customizing forge hammers, presses through dies, or casting tools through the production of molds, is one of the biggest labor bottlenecks in the manufacturing process today. The creation of these designated parts required for any specific production run is the task of the machinist, a position requiring a great deal of skill since it involves everything from designing the dies, cutting them through precision milling, and knowing how to repair them if they break or become defective.

In the early and mid-twentieth century, most manufacturing plants, like automotive companies, produced all of their own parts before assembling them. This means they owned all their own forges, presses, and employed machinists capable of customizing them to produce the parts they needed.

However, in the late twentieth century, this soon gave way to a system of specialization and outsourcing. Forges and presses are expensive and large. For manufacturers that wanted to run production lines of many products, producing every single component of each product would be prohibitively expensive. (For reference, a typical car contains somewhere on the order of 30,000 unique parts.) Not only do these machines take up valuable factory floor space, they are also extremely difficult to reorganize in the event that a product line needs to be altered.

As a result, it made more and more economic sense to order constituent parts from outside vendors who could execute batched production runs for their clients.

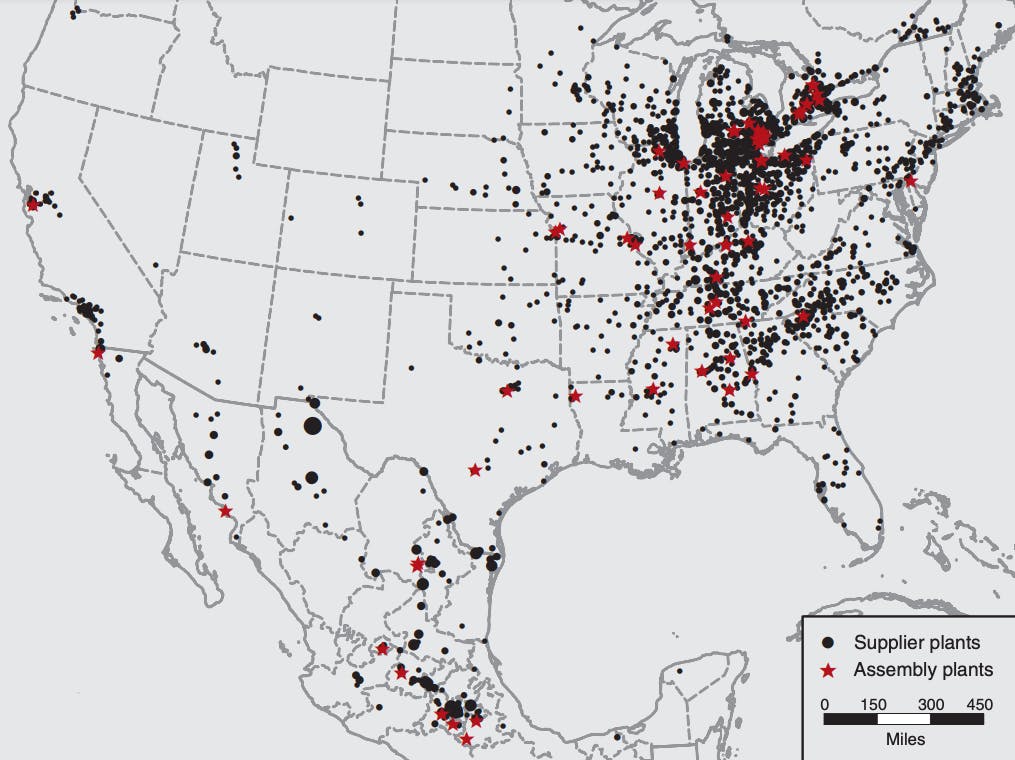

In 2008, geographer James Rubenstein and economist Thomas Klier wrote the book “Who Really Made Your Car?” to investigate the changing landscape of modern manufacturing, using the American automotive industry as a proxy. Their conclusions were fascinating. As the title of the book indicates, there’s a lot more complexity behind the manufacture of goods such as cars than it may appear. The map below shows the explosion of parts suppliers for every assembly plant that existed in 2008.

Source: Who Really Made Your Car?

Though outsourcing part production was cheaper than the alternative, it greatly increased the logistical complexity of the manufacturing process. Scheduling the arrival of parts in synchronization with active assembly lines was, and remains, a massive headache. Furthermore, Rubenstein and Klier noted that original manufacturers increasingly found themselves giving up more and more control over the specific design of their parts. “Instead of providing detailed specifications, carmakers are giving their direct suppliers responsibility for research and development to design and build innovative modules and systems,” they wrote.

Ultimately, many automakers began purchasing “large modules and systems ready to be installed on the final assembly line” rather than assembling all the supplied components themselves. This decentralization of production progressed to even greater extremes as parts production was outsourced to other countries, instead of just neighboring suppliers. Between 1978, when 19.6 million people were employed in the manufacturing sector in America, and 2020, a third of all American manufacturing jobs had been lost.

In recent years, the drawbacks associated with these shifts have been laid bare. Yossi Sheffi’s 2020 study of international production processes found that the interconnectedness of global supply chains meant that even small disturbances causing the delay of a single part, could produce massive upheaval to entire production runs. In that study, “For Want of a Nail,” he noted that “a 70-millisecond power dropout at Toshiba’s Yokkaichi memory-chip plant in late 2010 affected the world’s supply of NAND flash.”

Inflexible machines which made production lines rigid, alongside increasing logistical complexity which threatened the resilience of supply chains and complicated the manufacturing process hamstrung modern manufacturers and designers, who for many years have had to face difficult tradeoffs in the production of their goods.

Luckily then, in the same decade that manufacturing faced a historic decline in America, a new paradigm was on the rise. Today, that paradigm, known as additive manufacturing, is slowly changing the nature of goods production.

Additive manufacturing is defined by the capability to deposit material deliberately, layer-by-layer, to produce components far more intricate than what is possible with traditional subtractive manufacturing methods.

3D printers, some of the first additive technologies, became commercially available in the early 2000s. They were expensive, but allowed three-dimensional models stored digitally to be produced using polymer-based filaments. One of the first such printers was the MakerBot, which attempted to show the promise of the technology by 3D printing many of its own constituent parts, demonstrating the potential to self-replicate.

In 2009, when MakerBot was launched, there was still no such thing as an industrial-scale printer capable of producing high-quality components. The MakerBot, though impressive, was expensive and became a curio-tool for hobbyists, capable of printing things like combs, plastic figurines or small prototypes.

Remarkably, in just the ensuing decade, all that has changed. In 2023, nearly all new aircraft contain some 3D printed parts, while most aerospace or automotive design processes rely on 3D printing for prototyping essential to the production cycle. Essentially all custom hearing aids are 3D printed, as are dental products like teeth aligners. Some of the biggest footwear brands like Adidas and Nike rely on 3D printing to produce soles in many of their newest shoe models.

During the 2010s, additive manufacturing technology has come into its own, and demand for it has grown in tandem. Hubs, a 3D printing marketplace, ambitiously estimates that annual demand for 3D printing services will triple in size by 2026 to $44.5 billion.

General Electric put the possibilities of additive manufacturing on full display when they unveiled an experimental jet engine, called the Advanced Turboprop, one third of which was built using 3D printed parts. As a result, their engineers managed to reduce the engine’s components from over 800 down to just 12.

Already, high-end automotive companies like Aston Martin and others are experimenting with additive technology to produce parts with more complex geometries. In 2021, Czinger, a car manufacturer based in Los Angeles, produced its breakout hypercar, the 21C, which featured over 350 3D printed components including the chassis, suspension system as well as the induction and exhaust components of the engine. Meanwhile, Relativity Space 3D printed a reusable rocket, which it successfully launched into space in March 2023.

Source: Czinger

Though traditional manufacturing technologies like hammers, presses, and molds will likely always be critical features of production lines, in due time additive manufacturing is sure to become a hallmark of nearly all manufacturing processes. Building components up layer-by-layer not only allows for more intricate parts with complex internal structures to be produced, it also drastically reduces the amount of waste produced in traditional manufacturing.

Lower material costs, fewer parts required for assembly, and a more vertically-integrated production system are just some of the advantages offered by additive manufacturing. If it continues gaining traction, it is certain to alter the face of manufacturing as we know it.

A History of Manufacturing Process Innovations

Over the years, the arc of manufacturing has evolved from the skilled hands of the master to the present machine-based system capable of extreme precision and repeatability through a patchwork of process innovations hundreds of years in the making. Additive manufacturing is merely the latest in a long line of process innovations that have made manufacturing what it is today.

The Invention of Machine Tools

The first of these process innovations helped catapult the Industrial Revolution itself.

In the late 1700s, metal was already established as a material critical to building human civilization. However, the techniques that existed to manipulate metals were very limited. In particular, making large structures from metal typically required casting — melting the metal and pouring it into a mold.

The problem with this technique was that it produced a very brittle kind of metal, fine for pots and pans, but entirely unreliable when it came to casting, say, cannons.

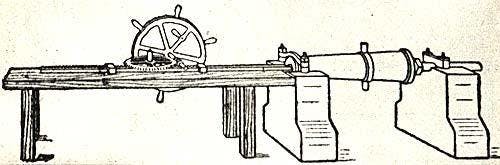

Often, cannons formed by casting developed cracks or displayed deformities. Over time, these bent the barrel of the cannon, changing the cannon’s arc when fired. One of the first innovations capable of remedying this problem, developed in 1775, was John Wilkinson’s lathe.

Source: Bantam Tools

The lathe consisted of a rotating cutting head which spun in a circular motion, powered by a water mill. The rotating motion allowed the cutting head to bore a precise cylinder through most types of metal. Thus, rather than casting cannons, with Wilkinson’s lathe, a perfect cylinder could be bored directly into the metal, producing an exact cannon chamber every time.

John Wilkinson’s lathe (or boring mill) was one of the first machines capable of producing accurate material transformations in metal. It was critical not merely for its applications in cannon production, but also due to its ability to produce cylindrical, metal steam chambers necessary for the invention of the first steam engine by James Watt.

Wilkinson’s lathe inspired the development of all machine tools that followed, including those capable of turning, drilling, milling, shaping and planing materials. It is these machines, and the repeatable transformations they allowed to be done on materials, which enabled the Industrial Revolution and all the economic reshuffling that ensued as a result.

The Revolution of Interchangeable Parts

Though the lathe and its descendants enabled a much quicker and more powerful way of shaping materials, until the 1800s, the actual production and assembly of individual goods was done on a very bespoke basis. There was still no standardization of goods production, even within individual manufacturers.

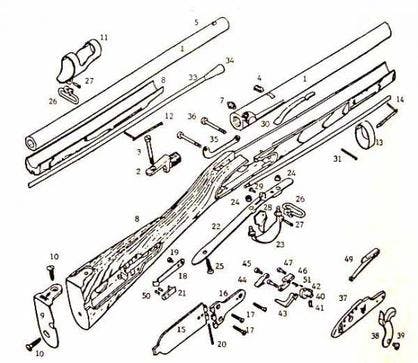

However, a better way was envisioned by Eli Whitney. Whitney was also known for his invention of the cotton gin, an important tool capable of mechanically removing sticky seeds from fibers in the cotton plant. Unfortunately, the cotton gin never made Whitney any money. Hence, he needed to turn to other ventures. So, in 1797, Whitney negotiated a contract with the U.S. government to produce 10,000 muskets using an entirely novel assembly method.

The traditional way of making guns involved custom fabricating each part and then hand-fitting the parts together by filing them. This meant that each gun was unique and the time it took to produce it was very great. Should a component of a soldier’s musket become defective in battle, there would be no hope of repairing it, since it would require a new custom part and custom fitting too. Whitney believed that all the necessary components of a musket could be made accurately enough to allow for assembly of the parts without fitting.

In 1801, he traveled to Washington to demonstrate this principle. He laid out all the components required to produce 10 muskets and assembled them in front of American government officials.

It was ‘The Mother of All Demos’ of its time, for it envisioned an entirely new methodology of manufacture. To achieve this, Whitney produced a set of extremely precise gauges which ensured the exact measurements of all the components required.

Source: Tech Advancements

Though Whitney was eight years late in delivering the 10,000 muskets, his idea of precisely manufactured components stuck and the system came to be known as the interchangeable parts system, or what is sometimes referred to as the “American System of Manufacture”. It would take many years before interchangeable parts could become practical among all producers, but the instantiation of this idea was critical for the era of mass manufacturing to come.

The Introduction of Precision

One of the most important missing components in manufacturing in Whitney’s time was a standardized system of measurement. Whitney had to make all his own gauges to measure out the parts because there was literally not a precise system of measurement that all manufacturers across the country shared. Even if a component needed to measure, say, two inches, there would be great variance and disagreement over what “two inches” really meant.

Around the time of the French Revolution, for instance, France had on the order of 250,000 different units of measurement. And so it was the French who eventually instituted the metric system in 1790, defining the meter as a 1/10,000,000th of the distance between the North Pole and the equator — a distance that the French literally measured. Between the years of 1792 and 1798, two surveyors set out to measure a portion of this distance (the part between Dunkirk and Barcelona) to get it right.

However, the most impactful of all new measurement protocols for manufacturing specifically was the Swedish inventor Carl Johansson’s system of gauges. Johansson’s gauges were a complex of extremely precisely cut rectangular parts which could be arranged in any way to calibrate machines and accurately measure the sizes of parts. The first set of Johansson’s gauges were purchased in 1908 by Henry M. Leland, the founder of both Cadillac and Lincoln. Twelve years later, Leland is known to have said “There are only two people I take off my hat to. One is the president of the United States and the other is Mr. Johansson from Sweden.”

Source: Herbert Hoffman

By 1923, Carl Johansson actually began work at Henry Ford’s automotive company. Though Henry Ford is credited with having brought about the era of mass manufacturing with his invention of the assembly line in 1913 — the formalization & standardization of the interchangeable parts revolution — it was Johansson’s system of accurate gauging and measurement that made the assembly line and mass manufacturing viable in the first place. It is said that only Henry Ford’s son and Johansson himself were able to enter Ford’s office without knocking.

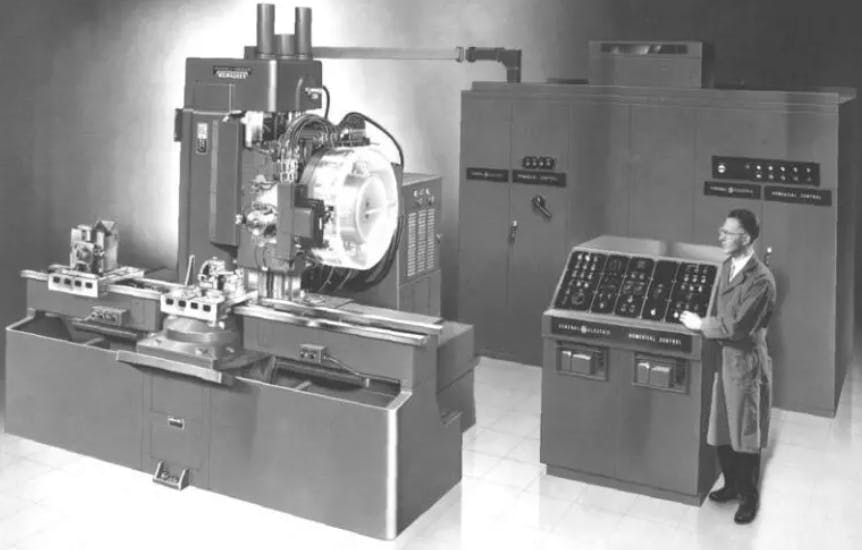

The Dawn of Computer Numerical Control (CNC)

The next most important innovation in manufacturing was the introduction of computer-guided milling machines. World War II demanded that quick and precise production of defense technology be possible over a vast volume of components. So, in the 1940s, John T. Parsons came up with the idea for how a computer program could guide the operation of a mill. A few years later, Richard Kegg at MIT successfully constructed the first machine capable of moving along Cartesian coordinates to enable precise machining.

Source: History of CNC machines

Today, the impact of CNC machines on industry cannot be overstated. They, along with computer-aided design (CAD) systems, which can encode 3D models of objects, are essential tools in the manufacturing industry.

Not only can they themselves manufacture extremely accurate parts, they are also critical in the creation of tools and dies used in more traditional material shaping techniques. However, a great deal of human involvement is still required to translate dictates of the CAD model into optimal instructions for the CNC machine.

The Promise and Challenges of Additive Manufacturing

Traditional 3D printing, which came to prominence in the early 2000s operated using a fused deposition modeling technique. This involved heating and extruding thermoplastic filaments in successive layers. However, the most impactful 3D printing technologies in industry are those capable of printing with metal.

The problem is that metal cannot be melted and extruded in the way that plastics are. Instead of being melted, the metal is ground down into a fine powder and then selectively fused together to produce a complete structure. This is the core concept underlying all industrial scale metal printing technology today. The main differences lie in how exactly the fusing happens.

The most common metal printers today rely on a technology called Selective Laser Sintering (SLS), which was developed in 1986 by Carl Deckard and Joe Beaman at the University of Texas at Austin. In SLS machines, the metal powder is first laid out on a flat bed. Then, a high-powered laser beam is carefully directed along the coordinates of the desired part, causing the metal powder to fuse together at precisely those spots until the desired solid is formed. The fusing must happen in a vacuum chamber since the heated metal powders could react explosively if exposed to oxygen. SLS machines are very versatile and can be used to fuse objects from a variety of metals including aluminum, cobalt-based alloys, nickel, titanium and even ceramics and plastics.

A cousin of the SLS technique is electron beam melting (EBM) which substitutes lasers with electron beams. Electron beams are larger than lasers, so this method sacrifices some of the precision of SLS for a quicker production process. Currently, General Electric is the only company that produces EBM machines.

Yet another alternative is binder jet printing, a technique developed at MIT in 1989 by Emmanuel Sachs, the man who coined the term “3D printing.” Just like SLS, binder jet printing lays out metal powders on a flat bed, but uses an ink jet overhead to deposit tiny droplets of a binding agent at specific locations. This binding agent acts like a glue, fusing the metal powder particles together at those points. After one layer is completed, a new layer of powder is spread over the top of the previous layer, and the process is repeated until the final object is formed. Afterwards, the entire printed object must be baked in a vacuum furnace to melt the binding agent away and make the structure fully metallic.

Binder jet printers are an exciting 3D metal printing technique since they are capable of operating multiple inkjets to print many objects at a time. Afterwards, multiple parts can be sintered in a vacuum furnace together, allowing for true batched production — something all other 3D metal printing techniques are currently lacking.

Source: Markforged

Though these modern industrial metal printers have already been used to produce components used in airplanes, jets and even cars, valued for their ability to generate highly complex structures unachievable by existing casting or CNC machining techniques, there are still important areas in which these technologies are lacking.

In the first place, metal 3D printing today is very expensive. Industrial metal 3D printers can run up to from hundreds of thousands to millions of dollars. Though they can produce parts quickly, depending on their scale, they are not suitable for mass production runs, since this would require the use of multiple machines which would render mass production economically prohibitive.

Furthermore, in contrast to CNC milling or other cutting and material shaping techniques that can achieve precision down to a thousandth of a millimeter, 3D printing is much less precise. Small voids and imperfections are produced in the resulting shapes, which may produce cracks. With continued wear, these cracks may grow, threatening the structural integrity of the material altogether.

As a result, it’s commonly understood that 3D metal printed parts fail much sooner than traditionally cut metal parts. To overcome some of these deficiencies and create quality, durable production parts out of 3D printed materials, post-processing is required. One example is surface machining, which works to strengthen the printed material. However, post-processing is yet another step which will increase the cost of producing 3D metal printed parts, thus only making this technology viable for ultra-large commercial manufacturers.

Perfecting the performance of 3D printers is really a question of material science. It will likely require discovering new techniques of manipulating materials in ways that we still have little to no experience with. Though current methods have shown some cracks, figuratively and literally, that doesn’t mean that new exciting prospects for 3D printed parts and materials don’t await on the horizon.

Every great process innovation in manufacturing took decades to fully be implemented and absorbed into traditional manufacturing systems, and it will likely take many more decades for the kinks with 3D printing to be worked out in full. However, even at this stage, it’s clear that additive manufacturing is an innovation on par with Whitney’s interchangeable parts revolution and even Johansson’s gages. Given the freedom, greater design complexity, lower material costs, and tighter feedback between design and production, additive manufacturing has opened new exciting avenues for goods production that we would be wise to continue exploring.

Disclosure: Nothing presented within this article is intended to constitute legal, business, investment or tax advice, and under no circumstances should any information provided herein be used or considered as an offer to sell or a solicitation of an offer to buy an interest in any investment fund managed by Contrary LLC (“Contrary”) nor does such information constitute an offer to provide investment advisory services. Information provided reflects Contrary’s views as of a time, whereby such views are subject to change at any point and Contrary shall not be obligated to provide notice of any change. Companies mentioned in this article may be a representative sample of portfolio companies in which Contrary has invested in which the author believes such companies fit the objective criteria stated in commentary, which do not reflect all investments made by Contrary. No assumptions should be made that investments listed above were or will be profitable. Due to various risks and uncertainties, actual events, results or the actual experience may differ materially from those reflected or contemplated in these statements. Nothing contained in this article may be relied upon as a guarantee or assurance as to the future success of any particular company. Past performance is not indicative of future results. A list of investments made by Contrary (excluding investments for which the issuer has not provided permission for Contrary to disclose publicly, Fund of Fund investments and investments in which total invested capital is no more than $50,000) is available at www.contrary.com/investments.

Certain information contained in here has been obtained from third-party sources, including from portfolio companies of funds managed by Contrary. While taken from sources believed to be reliable, Contrary has not independently verified such information and makes no representations about the enduring accuracy of the information or its appropriateness for a given situation. Charts and graphs provided within are for informational purposes solely and should not be relied upon when making any investment decision. Please see www.contrary.com/legal for additional important information.