What and how we eat is a product of deliberate design. As Tom Standage writes in An Edible History of Humanity, "a cultivated field of maize, or any other crop, is as man-made as a microchip, a magazine, or a missile."

Agriculture is one of the oldest technologies known to man. Over the millennia, its evolution has changed everything from our social structures to the geographic and genetic composition of the earth and its inhabitants.

History has wrangled with foes like resource scarcity, low yields and insufficient energy sources before. The clever inventions that have allowed our food systems to flourish and our population to explode in the previous sixty years from a population of just over 1 billion to a population of 8 billion are codified in the passages below. These incredible successes are worth studying, but they’re not where the story of agriculture ends.

As the global population continues to inch up to just under 10 billion by 2050, our food systems will face incredible tests, being called upon to produce more food in the next three decades than we have produced in our entire history combined. Meanwhile, the challenges posed by a changing climate, along with higher water and fertilizer prices, and a falling amount of arable land will only add additional pressures to our efforts.

Ingenious solutions are always inspired by clever ideas from the past — and as we begin to engineer the future of our food systems, we must also understand the technologies that brought us to where we are now.

Energy and Agriculture

Although agriculture has come a long way since the earliest days of the Neolithic, the underlying mechanism of food production remains fundamentally non-human. To this day, we rely on plants to do the hard work of converting sunlight and carbon dioxide into edible and energy-rich compounds for us via photosynthesis. Photosynthesis is a process humans are still very far from fully understanding and being able to replicate efficiently.

But just because we can't conduct photosynthesis ourselves doesn't mean we can't help the process along. Agriculture is really just this — a method of choreographing and enhancing unpredictable organic processes to behave more predictably.

That was the initial bet that hunter-gatherers made over 10,000 years ago when they turned to farming. Farming was more energy intensive than hunting animals in the wild, it required more work over longer periods of time, and required that humans stay tied to their land.

However, the high upfront investment also came with a high reward. Farming yielded 10 to 100 times more calories per acre than hunting and gathering. Over time, coordinated agriculture allowed larger populations to survive over smaller areas of land and carry on the traditions of farming across future generations.

Still, effective agricultural techniques took thousands of years of trial and error to develop. Large amounts of labor were needed to complete all the steps including moving the earth, sowing the land, irrigating crops, reaping and picking, thrashing, grinding and transforming grains and crops into edible foods.

The amount we were able to grow depended on the sources of energy we could call on to ease the difficult work. In this sense, the story of agriculture has always been deeply intertwined with the story of energy.

Without access to efficient energy sources for thousands of years, agricultural yield was capped for a similar amount of time. In ancient Egypt, the ratio of people to the amount of cultivated land needed to support them was roughly one Egyptian for every two acres. It took 3,500 years to bring that number up to one person per acre by the time that Egypt had become a province of the Roman Empire, and that's basically where it stayed until the 18th century.

The actual techniques of farming didn't change much in that time span. Engineering waterways for better crop irrigation had been practiced since 6,000 BC, and animals were already an integral part of food production. Their labor was essential to powering heavy plows and assisting in the most energy-intensive tasks.

By the mid 18th-century, history was already littered with examples of how soil erosion had sealed the fates of entire empires and communities, unable to feed their populations. Increasingly, problems with food scarcity and low output were beginning to be an increasingly common issue.

Europe was already facing other resource shortages. Lumber, used as both a construction material and fuel, was vanishing. European forests were becoming barren and lumber was trading at a record-breaking premium. It was around this time that Thomas Malthus, noting the circumstances, began to worry about the consequences of resource constraints on continued population growth. In 1782, he published his famous Essay on the Principle of Population which argued that great suffering would befall a society whose population grew faster than its ability to produce food and other resources.

Today, Malthusian thinking is ridiculed because this prediction turned out to be incorrect. Deaths from famine reached historic lows in the 21st century, but that ridicule suffers from hindsight bias. At the time of writing, Malthus could not have foreseen the discovery of a more powerful source of energy that would allow many parts of the food production process to be mechanized, thus tremendously increasing output. In other words, Malthus couldn't foresee coal.

Coal burned a lot longer than wood. Discovery of massive sources of coal reduced the dependency on lumber for fuel and allowed many physically intense parts of the food production process to be taken over by machines. Mechanical seed drills meant sowing no longer had to be done by hand. Mechanical harvesters would cut stalks faster. Threshing machines would separate wheat from chaff while granaries pounded on the separated grain to produce flour.

By 1900, thanks to the discovery of fossil fuel, crop growing and harvesting was seven times more efficient than it had been 100 years earlier.

Introduction to Fertilizer Science

Mechanization meant we could plant and reap more, but for the longest time, our understanding of what actually made plants grow was very hazy.

The 17th century was consumed with debates on whether water was the only input needed to help plants grow, or whether other elements in the air or in the soil played an important, yet invisible, role.

These early debates put us on the right track. We know today that plants can't grow without three nutrients in particular:

- Phosphorous, which is essential to photosynthesis, cell division and the synthesis of DNA

- Potassium, which helps plants regulate their water balance and is involved in the synthesis of proteins and carbohydrates

- Nitrogen, which is by far the most important of the three. Nitrogen is essential because it is a building block of chlorophyll, the pigment that makes plants green and allows them to convert sunlight into energy through photosynthesis.

Healthy, fertile soil replenishes these three elements through natural processes, making them available for plants. However, for thousands of years, humans have known that natural soil fertility could be augmented with the use of fertilizers, such as by layering manure on top or rotating your primary crops with leguminous species like alfalfa or soybeans.

Legumes somehow always replenished the soil they were planted in, but the underlying mechanism was not understood for thousands of years. The Greek philosopher Theophrastus, who lived around the 3rd century BC, said "the bean best reinvigorates the ground," and even Cato the Elder, living in the 2nd century BC, advised farmers to plant leguminous varieties "not so much for the immediate return as with a view to the year later."

The secret that made these techniques effective, which eluded early generations that practiced them, was their ability to infuse the earth with nitrogen. All biological processes rely on this element, normally found as a gas, floating everywhere around us at all times. It's a building block of proteins and DNA, but we can't get it from breathing it in. Humans get nitrogen from eating animals or plants, which in turn absorb it from the soil.

There are only a handful of natural processes that can convert gaseous atmospheric nitrogen into the kind of compound that plants can soak up through their roots. As far as we know, only a few species of bacteria are able to do this. These bacteria have enzymes which can convert atmospheric nitrogen (N2) into ammonia (NH3), but they are sensitive to oxygen, and so the entire process must take place anaerobically.

Leguminous crops, like various sorts of beans, have tiny nodules in their roots that provide shelter and an oxygen-free environment where bacteria can conduct these operations in peace. Soybeans, alfalfa plants and other legumes evolved symbiotically with nitrogen-fixing bacterias, and now possess the superpower of regenerating soil fertility merely by being planted!

It was not until the end of the 19th century, however, that the inner workings of the nitrogen cycle and its importance to organic life were discovered. Our awakening to the importance of nitrogen spurred a mad dash for any compounds that contained it. Alas, the only source of mineable, soluble nitrogen was found in the deserts of Chile, which quickly became the world's greatest exporter of nitrates and a crucial geopolitical player as a result.

The holy grail of agriculture, of course, would be a technology that could synthesize soluble nitrogen out of the air, circumventing the need to rely on bacteria or Chilean exports. It was a challenging feat of chemistry, and few scientists believed it was even possible.

It was ultimately a man named Fritz Haber who figured it out in the early 20th century. He grew up in a merchant household, with his father trading dyes, lacquers, and other chemical compounds. Having been surrounded by chemicals his whole life, Haber went on to study chemistry, and ultimately apply his learning to solving the greatest chemical conundrum of his day — synthesizing soluble nitrogen in the form of ammonia.

Around the turn of the 20th century, solving this puzzle was becoming particularly valuable since ammonia and other nitrogenous compounds were an important ingredient in explosives. With the impending outbreak of World War I, it was in the interest of every nation to get its hands on as much ammonia as possible without risk of being cut off from supply.

Around this time, Haber was working as something of an 'entrepreneur-in-residence' at BASF (the “Baden Aniline and Soda Factory”), a giant of German industry which remains the largest chemical producer in the world to this day. BASF would pay him a salary, and in exchange, Haber would devote all his time to researching the synthesis of ammonia. If anything of note was discovered by his research, BASF would retain the intellectual property.

Iterating on years of trial and error by the scientists that preceded him, Haber and his assistant discovered, as if by a stroke of luck, the precise conditions required to make ammonia out of nitrogen and hydrogen gases. Mixing these two gases together, while simultaneously subjecting them to a pressure of 200 atmospheres and a temperature of 600 degrees Celsius, was what did the trick.

BASF representatives trembled with excitement upon seeing Haber's invention drip liquid ammonia before their eyes. The only problem was that Haber's contraption was 75 cm tall, and could only produce a few milligrams of ammonia every few hours. BASF wasn't interested in milligrams of the stuff, but tons, so it appointed an internal employee, Carl Bosch, to figure out how to recreate the procedure at an industrial scale.

Bosch wasn't as much a chemist as a metallurgist, an important background given that the main challenge before him was figuring out how to create an industrial-scale system that could withstand 200 atmospheres and 600 degrees Celsius without breaking or melting. Within four years he figured it out, and by 1913 he presided over the construction of the first plant to synthesize ammonia in the world.

Haber was awarded the Nobel prize for his efforts in 1918, and Bosch won the Nobel in 1931. Bosch was the first scientist working in the private sector to ever win the award.

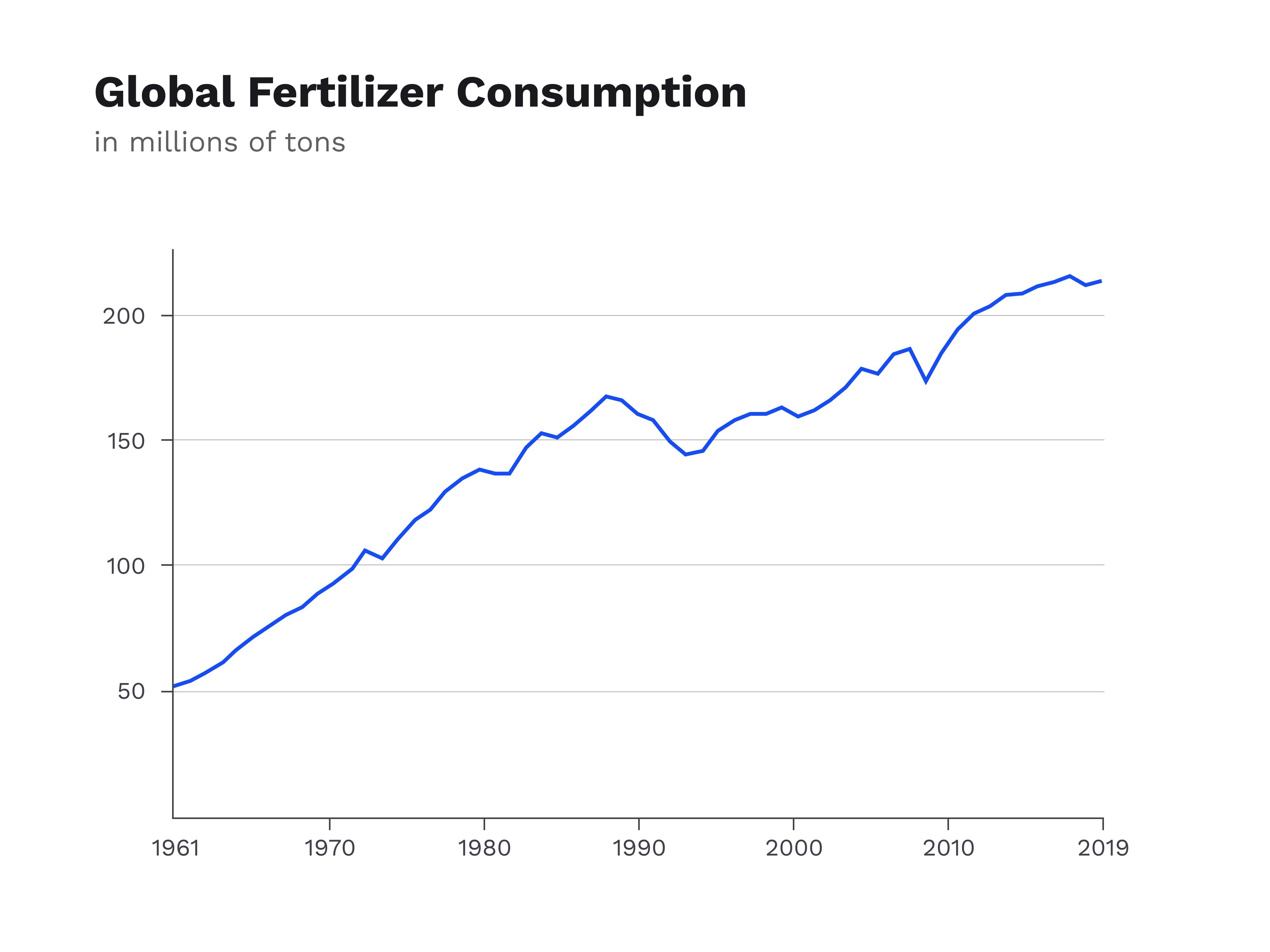

It's hard to overstate just how important this invention really was. Until then, nitrogen was the limiting factor in all agricultural output. After the invention of the Haber-Bosch process, that limit was rendered obsolete. Synthesizing ammonia meant that plant fertilizer could now be produced through industrial means for the first time. Over the course of the 20th century, the global population shot up from 1.6 billion people to 6 billion, and soon the Haber-Bosch process was responsible for producing more ammonia than the entire terrestrial nitrogen cycle itself.

The Green Revolution

The same year that BASF's ammonia plant got up and running, American tycoon John D. Rockefeller was incorporating the Rockefeller Foundation. Rockefeller had so much money that he needed to set up an entire philanthropic operation to donate it efficiently. Rather than donating to individuals in need directly, the Foundation decided to focus on tackling problems at their root.

One of the greatest such root problems confronting the world was famine and poor harvests in certain parts of the world. The Rockefeller Foundation decided to tackle these issues by hiring Norman Borlaug, an American agronomist, to study different species of wheat to discover whether a genetic super plant could be bred by crossing different varietals.

Borlaug set up shop in Mexico, which was suffering acutely from low crop yields despite being home to a wealth of genetic diversity. It took him nearly twenty years of research to examine thousands of wheat variants; finally, in 1962, he introduced a variety of wheat so impressive that in the following year, Mexico was yielding six times what it normally grew. That same year, Mexico went from being a net importer of grain to being a net exporter.

On the back of Borlaug's success, the International Rice Research Institute was founded in the 60s to breed the best yielding, fastest growing rice crop the world had ever seen. This time, the Institute was funded by two American philanthropic endowments, the Rockefeller and the Ford Foundations. The Institute examined over 10,000 varieties of rice to find the strongest and most nutritious strains to cross. By 1966, the mission succeeded. A strain of rice called IR-8 was developed, which was a cross between a Philippine and a Taiwanese varietal that could produce three harvests per year and yield roughly five times as much as other varieties of rice. Some started giving it the nickname "miracle rice."

The combination of genetic experimentation amplified by the copious availability of synthetic fertilizer launched an unprecedented global agricultural boom called "The Green Revolution."

The technologies introduced by the Green Revolution re-organized industrial agriculture. For one, they completely decoupled the process of growing crops from animal husbandry. In the past, animals were one of the only available sources of fertilizer. The ability to synthesize ammonia changed that. Farms didn't have to do both anymore, so growing crops and growing livestock became their own isolated specialties with their own economies of scale. Faster growing crops meant cheaper feed for animals, which meant cheaper meat production. Central feeding operations soon constituted the bulk of all poultry and cattle production in America.

The Green Revolution also produced a number of unsavory environmental externalities. Heavy use of fertilizer contributed to large amounts of chemical run-offs which harmed neighboring ecosystems. Increased use of water required to irrigate all the new crops being grown led to lower water tables and depleted aquifers around the world. Finally, intense farming practices left little time for land to lay fallow and naturally regenerate essential elements, depleting natural soil fertility and making farming even more dependent on the use of synthetic fertilizer.

The Future of Agriculture

The problem of agriculture is the same as it has always been. What's the most resource-efficient way to grow enough food to feed everyone on Earth? The only difference is that to feed a world population soon approaching 10 billion, we will need to produce more food in the next thirty years than we have produced during our entire history, while factoring in more constraints than we have had to deal with in the past.

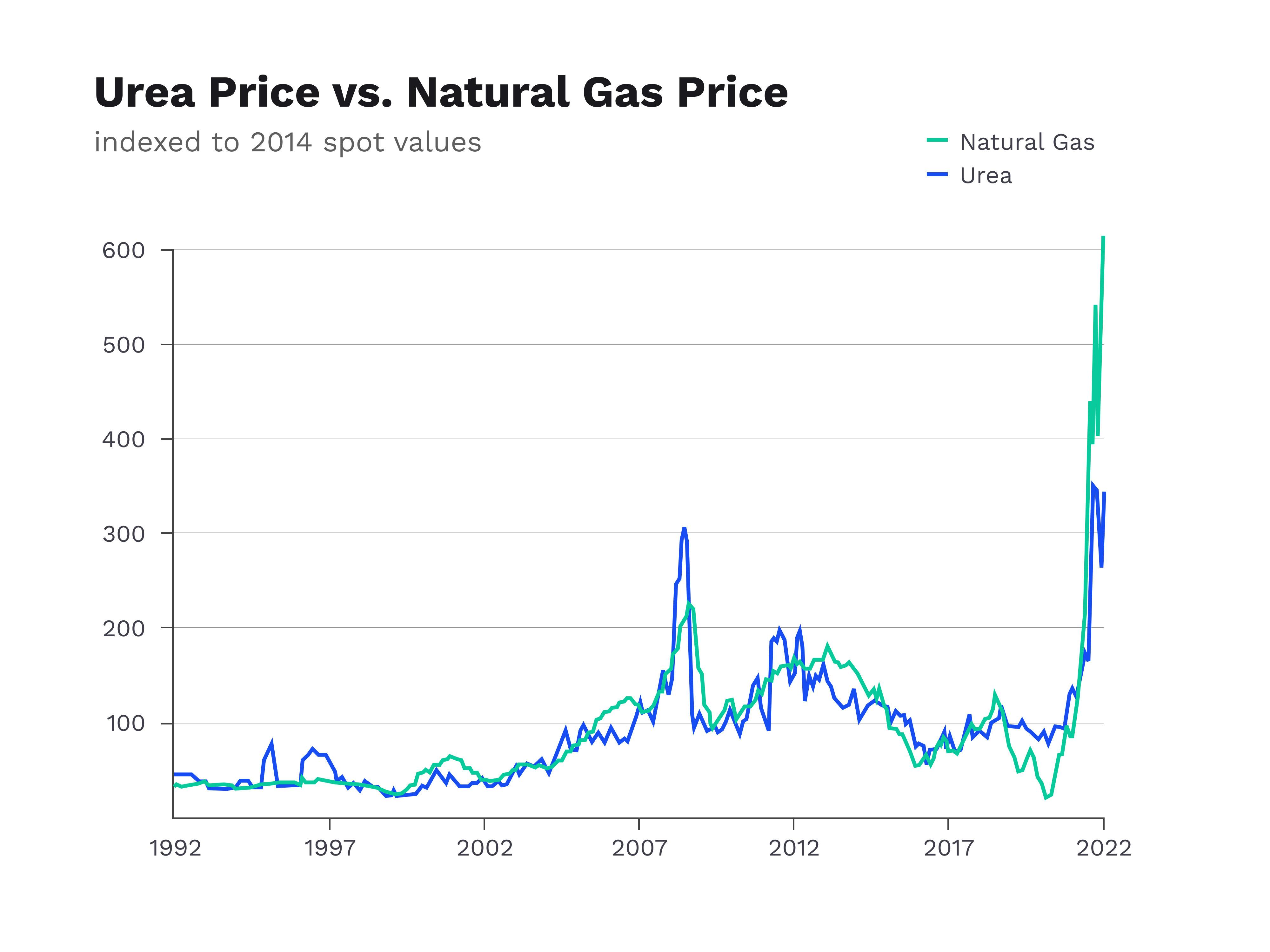

For one, the amount of arable land is falling over time, as more soil is eroded by intense farming. Jeremy Grantham suggests that half of all arable farmland, if not more, has eroded since the beginning of agriculture. For another, many are growing concerned about the use of fossil fuels like natural gas in the production of ammonia. Ammonia consists of three parts hydrogen, to one part nitrogen. The nitrogen we extract from the air, but the hydrogen is removed from methane or natural gas, which has become the most important input in producing fertilizer.

The vulnerability of having such a close link between fuel and food was made evident in the aftermath of Russia's 2022 invasion of Ukraine. With Russian natural gas embargoed, fertilizer prices around the world shot up, causing increases in the cost of food. A full year after Russia began its war, food prices are still elevated and slow to fall. Finally, further changes in the Earth's climate will undoubtedly impact the cost of inputs to grow food and the yields of planted crops.

One solution to the problems caused by a changing climate is the growth of the indoor farming movement. Controlled environment agriculture, as it's also called, is meant to provide consistent harvests with year-round availability.

The essential advantage of indoor farms, which really look like industrial greenhouses, is their ability to shelter and precisely control the growing environment of crops all while minimizing the amount of space required to grow crops.

Growing produce in nutrient rich solutions has obviated the need for soil, and has meant that plants can now be stacked vertically, further maximizing use of space in farming.

Indoor farming also places high emphasis on artificial light to help plants grow year round, even in less sunnier seasons, and the practice became more commercially viable when LED technology improved to the point that growers could place lights close enough to the plants without damaging them. This, in turn, helped indoor farmers fit even more growing produce into the same area.

One of the leaders and pioneers of indoor farming technology is the Netherlands, which thanks to this technology has become the second largest exporter of agriculture by dollar value, second only to the US, despite it having a landmass that is 270 times smaller.

This scale of production is made possible through the "precision farming" techniques employed in these greenhouses. Drones and special sensors test for everything from soil chemistry, water content, nutrients and rate of plant growth. Precise monitoring software has also enabled farmers to be more economical with inputs. From 2000, Dutch farmers have reduced dependence on water by 90% for certain crops, and have nearly entirely eliminated the use of chemical pesticides.

Part of the Dutch success story, however, lies in the fact that it once had access to incredibly cheap domestic natural gas. Cheap energy was essential for lighting and heating some of these massive indoor farming operations — and these greenhouses really are massive. Nearly 80% of Dutch cultivated land is technically "indoors", or under a greenhouse.

Still, the yields from these operations are impressive. An indoor acre can yield as much as 10 outdoor acres for certain crops, and cut the need for chemicals by 97%.

It's no wonder they've also become quite popular in the United States, which imports most of its vegetables in the summer months, and is becoming increasingly interested in growing more produce locally. The approach has succeeded here for certain varieties. For instance, 60% of all fresh tomatoes consumed in the US are grown in controlled environments. Recently, a number of companies from Plenty to AppHarvest have been investing in spreading the footprint of Dutch-inspired technology in the US. AppHarvest, in particular, built the largest greenhouse in the United States in Kentucky in 2021, is taking advantage of Dutch-made software, and is employing clever methods, like collecting and filtering rainwater to irrigate their crops and reduce costs as much as possible.

The expansion of closed environment, or closed-loop, systems are succeeding beyond just produce. The ability to precisely control all growing conditions and reduce environmental externalities has captured the imaginations of producers around the world.

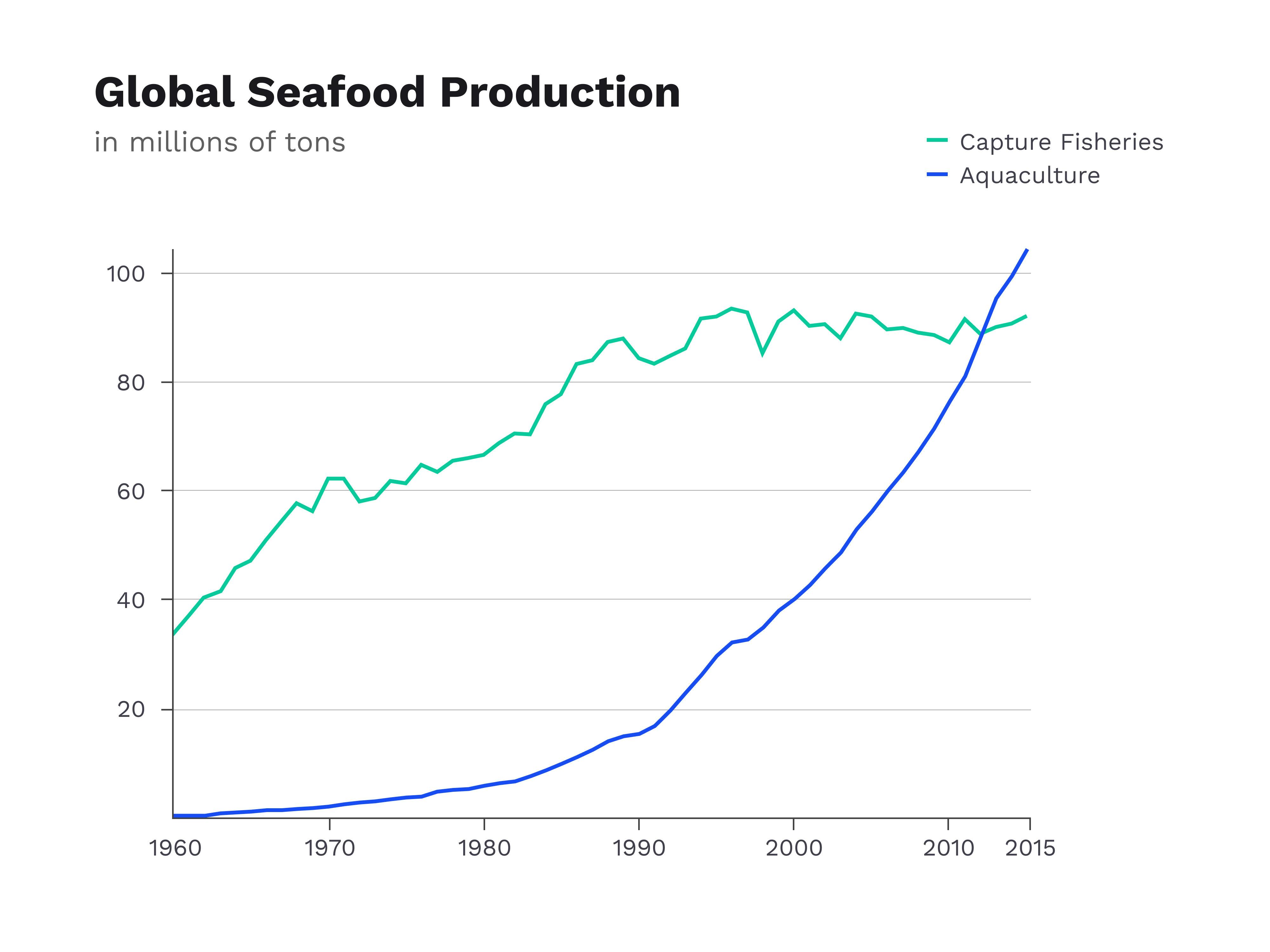

Aquaculture is another example where the trend has taken off. The majority of aquaculture, or fish farming, looks like open-ocean nets in which thousands of fish are bred. These operations have gotten so successful at producing fish that aquaculture now exceeds global beef production by weight, and even exceeds the market for wild-caught fish.

There are some emerging concerns, however, about open-ocean farms. The propensity for the fish to more easily spread diseases, sea lice and other nasty things is one of them. The pollution released into the ocean by the chemicals and the fish is another.

Closed-loop fish farms, typically meaning indoor tanks, can avoid imposing an externality on the ocean and more closely monitor the conditions for the fish.

Still, it's expensive to reproduce an environment and artificially supply it with all its energy and nutrient needs — especially when this involves recreating oceanic conditions indoors. In closed-loop fishing, constant energy is required to keep the water clean and cooled to the right temperature. Also not all crops can be grown indoors. Tall, vertical grain crops, which the world still depends on as its primary source of calories, just isn't economically feasible to produce inside. Continuing to produce sufficient quantities of crops while responding to the growing challenges of soil erosion, water depletion, and the economical production of fertilizer will be some of the most important challenges of the coming decades.

The future of growing foods, whether its wheat in the field, lettuce in a greenhouse, mackerel in a tank, or meat in a lab, will need to evolve constantly in response to the changes nature throws our way. The world's oldest technology, agriculture, thus will never be finished or perfected. Its future is destined to involve as much problem solving going forward as it took to get us here today.

Below are the companies working on the biggest challenges in food production:

1. Inari is building a gene modification platform that can fine-tune plant genetics in important crops like corn, soybeans and wheat.

2. AgBiome is creating a database of microbes that can produce more nutrients for crops, and help them fight off harmful fungi and pests.

3. Gingko Bioworks is using genetic engineering techniques to produce strains of bacteria which can help crops fertilize themselves.

4. Orchard Robotics is using computer vision to give farmers more accurate, total data on the trees in their orchards.

5. Bowery Farming uses vertical farming and sophisticated computer-based techniques to grow and sell lettuce, leafy greens, and herbs at over 850 stores throughout the US.

6. Plenty is another controlled environment agriculture company that uses vertical farming and computer-based techniques to grow and sell produce.

7. Whole Oceans is building one of the largest land-based aquaculture facilities to grow Atlantic salmon in Bucksport, Maine.

Disclosure: Nothing presented within this article is intended to constitute legal, business, investment or tax advice, and under no circumstances should any information provided herein be used or considered as an offer to sell or a solicitation of an offer to buy an interest in any investment fund managed by Contrary LLC (“Contrary”) nor does such information constitute an offer to provide investment advisory services. Information provided reflects Contrary’s views as of a time, whereby such views are subject to change at any point and Contrary shall not be obligated to provide notice of any change. Companies mentioned in this article may be a representative sample of portfolio companies in which Contrary has invested in which the author believes such companies fit the objective criteria stated in commentary, which do not reflect all investments made by Contrary. No assumptions should be made that investments listed above were or will be profitable. Due to various risks and uncertainties, actual events, results or the actual experience may differ materially from those reflected or contemplated in these statements. Nothing contained in this article may be relied upon as a guarantee or assurance as to the future success of any particular company. Past performance is not indicative of future results. A list of investments made by Contrary (excluding investments for which the issuer has not provided permission for Contrary to disclose publicly, Fund of Fund investments and investments in which total invested capital is no more than $50,000) is available at www.contrary.com/investments.

Certain information contained in here has been obtained from third-party sources, including from portfolio companies of funds managed by Contrary. While taken from sources believed to be reliable, Contrary has not independently verified such information and makes no representations about the enduring accuracy of the information or its appropriateness for a given situation. Charts and graphs provided within are for informational purposes solely and should not be relied upon when making any investment decision. Please see www.contrary.com/legal for additional important information.